23

PREP

ARING THE

APPLIANCE

APPLIANCE SAFETY

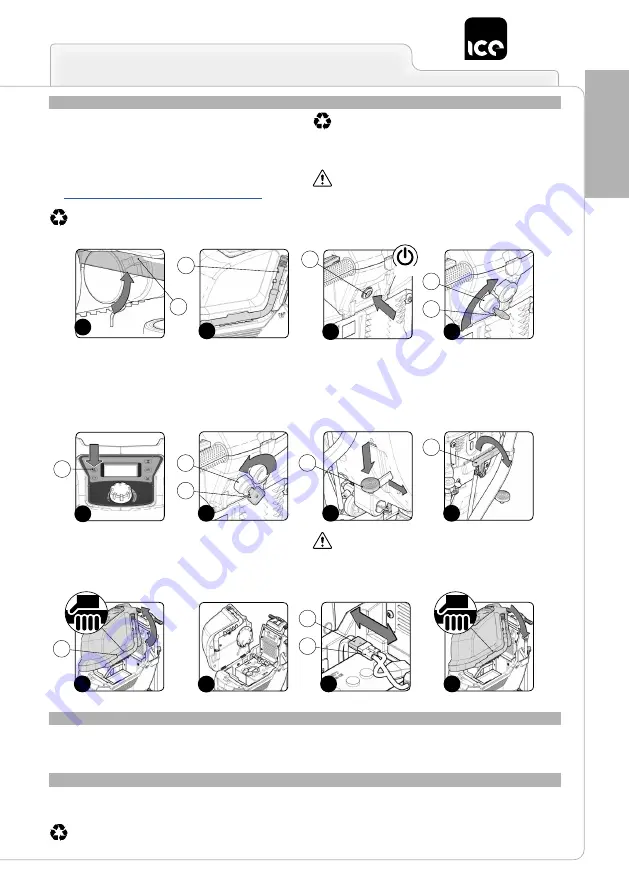

The stages for making the appliance safe, and thereby allowing all

the operations to be carried out in complete safety, are as follows:

1. For traction versions, make sure the electronic brake is engaged

by turning the lever (1) in the rear right part of the machine

counter-clockwise (

Fig.1

).

2. Check that the recovery tank is empty, if not, empty it with the tube

(2) on the left side of the appliance (

Fig.2

) (read the paragraph

CHECKING AND CLEANING THE RECOVERY TANK

”).

ATTENTION:

The tanks should be emptied in the place used

for draining dirty water.

ATTENTION:

the place designated for this operation must

comply with current environmental protection regulations.

3. For 50D versions, make sure the device is switched off. If it isn't,

press the main switch (3) on the back of the device (

Fig.3

).

ATTENTION:

in 50D versions, the main switch (3) is in the idle

position when the LED inside it is OFF and the activation

symbol is not visible.

4. For versions with PM, start the appliance, turn the main switch (4)

to "I", making a quarter turn to the right with the key (5)

Fig.4)

).

5. Lower the brush head unit, press the “BRUSH HEAD COMMAND”

button (6) on the control panel (

Fig.5

).

6. For traction and PM versions, switch off the machine by bringing

the main switch (4) to "0" and making a quarter turn to the left with

the key (5)

Fig.6)

). Remove the key from the instrument panel.

7. For versions without PM, bring the brush head into contact with

the floor, using the brush head control pedal (7) (

Fig.7

).

8.

Bring the squeegee into contact with the floor, turn the squeegee

control lever (8) counter-clockwise (

Fig.8

).

9. Grip the handle (9) on the left side of the recovery tank (

Fig.9

) and

turn the tank as far as it will go, until it reaches the maintenance

position (

Fig.10

).

10. Disconnect the connector of the general system (10) from the

connector of the batteries (11) (

Fig.11

).

ATTENTION:

This process must be carried out by qualified

personnel.

11. Grip the handle on the left side of the recovery tank and turn the

tank until it reaches the work position (

Fig.12

).

TYPE OF BATTERY TO BE USED

Power to the machine must be supplied by two sealed traction batteries with gas recombination or gel technology.

The batteries must meet the requirements laid out in the norms: CEI EN 60254-1:2005-12 (CEI 21-5) + CEI EN 60254-2:2008-06 (CEI 21-7).

For a good operating performance, we suggest the use of two 12V MFP 77 Ah/C5 batteries.

BATTERY MAINTENANCE AND DISPOSAL

For maintenance and recharging, respect the instructions provided by the battery manufacturer. When the battery reaches the end of its

working life, it must be disconnected by expert, trained personnel then removed from the battery compartment with the aid of suitable lifting

devices.

ATTENTION:

dead batteries are classified as dangerous waste and as such must be delivered to an authorised body for disposal.

1

2

1

2

5

5

3

4

4

3

6

4

OFF

9

10

9

11

11

10

12

8

7

8

7

6

5