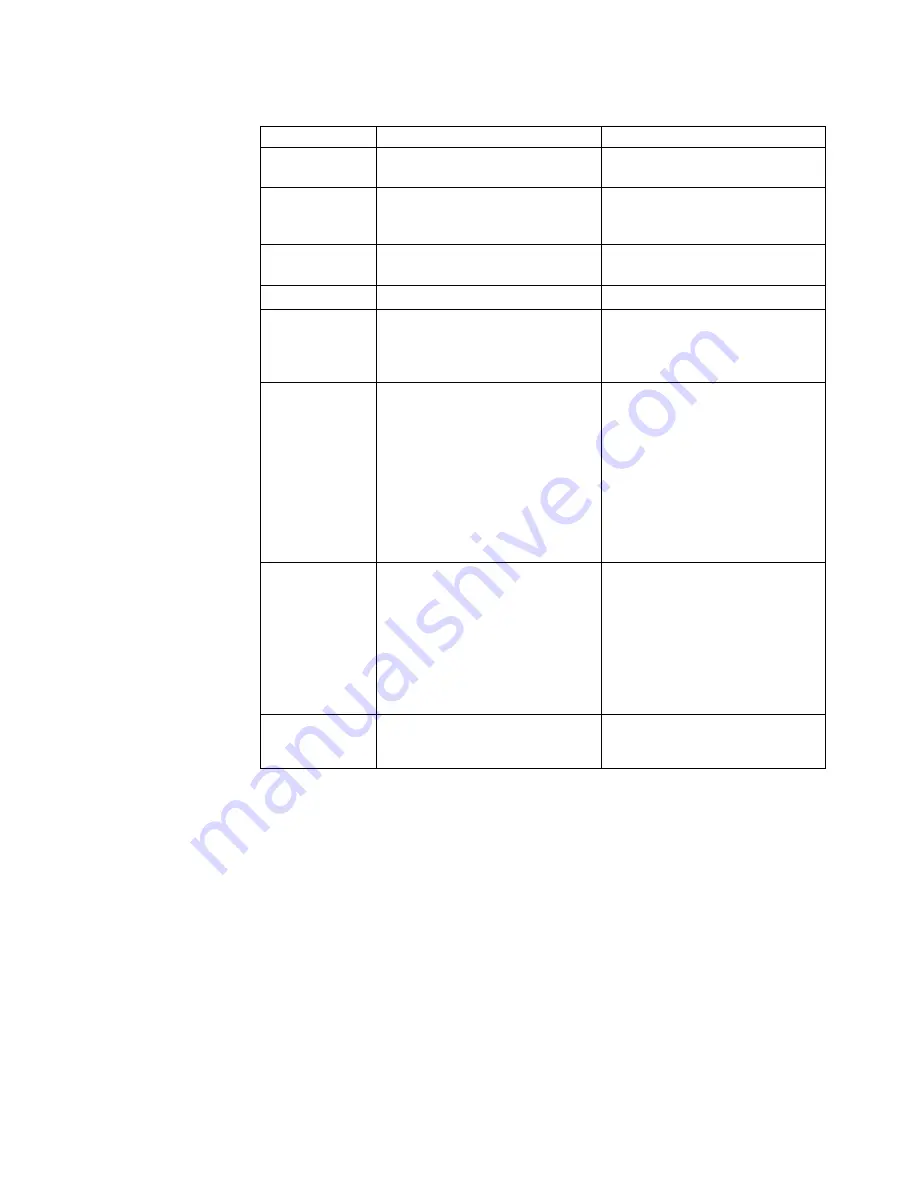

Environmental requirements

Condition

Operational

Non-operational (storage)

Ambient

temperature

0°C to 40°C (32°F to 104°F)

-25°C to 70°C (-13°F to 158°F)

Relative

humidity

(non-condensing)

5% to 93% at 40°C (104°F) with

maximum gradient of 10% per

hour

10% to 93% at 70°C (158°F)

Altitude (above

sea level

0 to 3000 m (10,000 feet)

0 to 12000 m (40,000 feet)

Shock

10 G, 11 ms, half-sine wave

20 G, 11 ms, half-sine wave

Vibration

Random vibration is 5-10Hz @

+5db/Oct; 10-200Hz @

0.0005Grms; 200-500Hz @

-5db/Oct. Scale 0.05 Grms

Random Vibration is 3-10Hz @

+5db/Oct; 10-200Hz @

0.0065Grms; 200-500Hz @

-5db/Oct. Scale 1.12 Grms

Air flow

SAN512B-6 Maximum: 1711 cmh

(1007 cfm)

SAN512B-6 Nominal: ~985 cmh

(~580 cfm)

SAN256B-6 Maximum: 953 cmh

(561 cfm)

SAN256B-6 Nominal: ~ 486 cmh

(~286 cfm)

N/A

Heat dissipation

SAN256B-6 - refer to Watts and

Btu/hr values under VAC inputs

in Typical, Idle, and Maximum

Power Consumption tables.

SAN512B-6- refer to Watts and

Btu/hr values under VAC inputs

in Typical, Idle, and Maximum

Power Consumption tables.

N/A

Operating noise

SAN256B-6: 64.2 dB

SAN512B-6: 68.2 dB

N/A

Power supply requirements

The minimum number of power supplies needed in your system for operation and

to achieve redundancy depends on the blade and port configuration and the AC

input voltage level. N is minimum number of power supplies to operate

configuration, N+N doubles power supplies for full AC input and DC output

redundancy, and N+1 adds additional power supply for DC output redundancy in

case of single power supply failure. Although examples for different port and

blade configurations are provided, for more information and help with

determining the actual number of power supplies for your deployment, contact

your local representative.

Appendix B. Product specifications

241

Summary of Contents for SAN512B-6

Page 2: ......

Page 8: ...vi SAN512B 6 Installation Service and User Guide...

Page 10: ...viii SAN512B 6 Installation Service and User Guide...

Page 12: ...x SAN512B 6 Installation Service and User Guide...

Page 40: ...16 SAN512B 6 Installation Service and User Guide...

Page 60: ...36 SAN512B 6 Installation Service and User Guide...

Page 128: ...104 SAN512B 6 Installation Service and User Guide...

Page 140: ...116 SAN512B 6 Installation Service and User Guide...

Page 170: ...146 SAN512B 6 Installation Service and User Guide...

Page 184: ...160 SAN512B 6 Installation Service and User Guide...

Page 196: ...172 SAN512B 6 Installation Service and User Guide...

Page 208: ...184 SAN512B 6 Installation Service and User Guide...

Page 258: ...234 SAN512B 6 Installation Service and User Guide...

Page 274: ...250 SAN512B 6 Installation Service and User Guide...

Page 285: ......

Page 286: ...IBM Part Number 01JC152 Printed in USA SC27 8966 02 1P P N 01JC152...