1-10

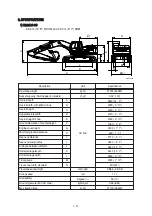

GROUP 2 SPECIFICATIONS

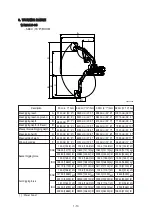

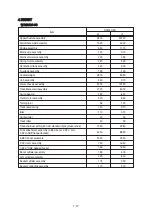

GROUP 2 SPECIFICATIONS

Hydraulic tank Main pump

Fuel tank

Battery box

Engine

Oil cooler

Turning joint

Radiator

Main control valve

Swing motor

Bucket

Tooth

Cab

Boom cylinder

Boom

Arm cylinder

Arm

Muffler

Counterweight

Bucket cylinder

Side cutter

Connecting link

Connecting rod

Idler

Track roller

Carrier roller

Track

Sprocket

Travel motor

Swing bearing

2209S2SP01

Connecting rod

Summary of Contents for Robex 220LC-9S

Page 1: ...Robex 220LC 9S CRAWLER EXCAVATOR SERVICE MANUAL...

Page 9: ...Group 7 Work Equipment 647 Find manuals at https best manuals com...

Page 18: ...SECTION 1 GENERAL SECTION 1 GENERAL Group 1 Safety Hints 1 1 Group 2 Specifications 1 10...

Page 41: ...This as a preview PDF file from best manuals com Download full PDF manual at best manuals com...