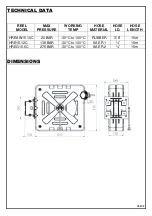

S580/4

IMPORTANT WARNING NOTES

Read carefully and understand all instructions before operating. Failure to

follow the safety rules and other basic safety precautions may result in

serious personal injury. Keep these instructions in a safe place and on

hand so that they can be read when required.

SAFETY PRECAUTIONS

1. Read and understand all instructions.

2. The warnings, cautions, and instructions discussed in this instruction

manual cannot cover all possible conditions or situations that could

occur whilst operating this hose reel. It must be understood that common

sense and caution need to be applied by the operator.

3. Use suitable personal protective equipment when assembling, operating

or maintaining this hose reel.

4. Ensure that the reel is properly installed before connecting inlet or outlet

hoses.

5. Bleed fluid or gas pressure from the system before servicing the reel.

6. Before connecting the reel to the supply ensure that the pressure does

not exceed the maximum working pressure rating of the reel.

7. If a leak occurs or if the reel ceases to unwind or rewind remove system

pressure immediately.

PRODUCT DESCRIPTION

Heavy-duty steel constructed cased hose reel supplied with hose.

Designed for delivering oil, water or grease (model dependent). The reel

can be wall, ceiling, bench or floor mounted.