28

3

Fuel system

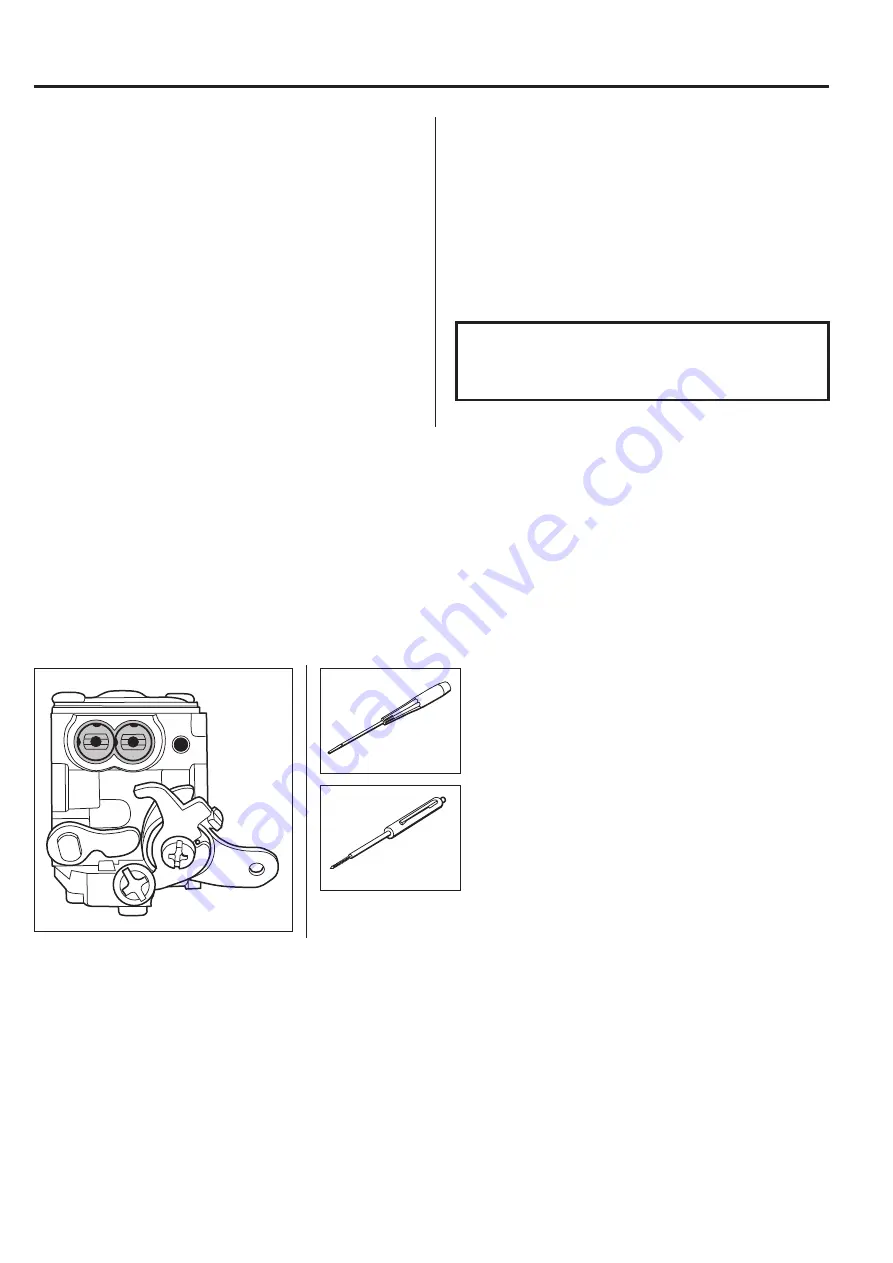

531 00 48-63

531 03 03-98

Setting the L needle

1. Fit the trimmer head T35 and use 2.7 mm plain cord. The

cord length should be as standard, i.e. reach the knife on the

trimmer guard.

2. Run the engine warm for about 5 minutes.

3. Turn the L-needle so that the highest speed is attained.

4. If the speed exceeds 3,700 rpm, reduce it with the aid of the

idling speed’s T-screw (T) and a carry out a new adjustment

in accordance with point 3.

5. Then turn the L-needle anticlockwise so that the speed drops

by 300 rpm.

6. Then adjust the idling speed to 2,800 rpm by turning the T-

screw.

7. When mounting the sleeve on the L needle, the needle is

turned a quarter-turn anticlockwise once the optimal setting

has been made and the sleeve is mounted so that the

needle cannot be turned anticlockwise. Now turn the L

needle back a quarter-turn.

Setting the H needle

1. Fit the trimmer head T35 and use 2.7 mm plain cord.

The cord length should be as standard, i.e. reach the

knife on the trimmer guard.

2. Run the engine warm for about 5 minutes.

3. Turn the H-needle so that the highest speed is attained.

4. Reduce the speed by 400 rpm by turning the H needle

anticlockwise. Fit the sleeve on the H needle so that it

cannot be turned anti-clockwise.

5. Then increase the speed by 200 rpm by turning the H-

needle clockwise.

NOTE!

If the cutting equipment rotates while idling the T-

screw should be turned anticlockwise until it stops

rotating.

Using a screwdriver 531 00 48-63 it is possible to make

small adjustments to the jet needles without the need of

removing the locking plugs.

H

L

Use the tool 531 03 03-98 to dismantle the locking plugs

(left-hand threads) so the needles can be screwed out,

e.g. for replacing or cleaning.

Summary of Contents for 333R

Page 1: ...Workshop manual 333R 335R English ...

Page 2: ......

Page 36: ...34 4 Centrifugal clutch ...

Page 40: ...38 5 Angle gear ...

Page 50: ...48 6 Cylinder and piston ...

Page 60: ......

Page 61: ......

Page 62: ...2005W23 115 00 92 26 ...