6

ASSEMBLY / PRE-OPERATION

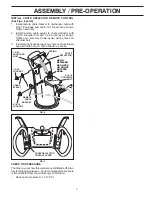

INSTALL DISCHARGE CHUTE / CHUTE ROTATER

HEAD (See Fig. 7)

NOTE:

The multi-wrench provided in your parts bag may

be used to install the chute rotater head.

1. Place discharge chute assembly on top of chute base

with discharge opening toward front of snow thrower.

2. Position chute rotater head over chute bracket. If nec es-

sary, rotate chute assembly to align square and pin on un-

der side of chute rotater head with holes in chute brack et.

3. With chute rotater head and chute bracket aligned,

po si tion chute rotater head on pin and threaded stud

of mounting bracket.

4. Install 3/8 washer and locknut on threaded stud and

tighten securely.

CHUTE

ROTATER

HEAD

3/8 WASHER

3/8 LOCKNUT

THREADED

STUD

PIN

ROTATER HEAD

MOUNT ING

BRACKET

CHUTE

BRACKET

FIG. 7

ALIGN BEFORE

TIGHTENING LOCKNUT

AUGER

CONTROL

LEVER

AUGER CONTROL ROD

AUGER

CONTROL

BRACKET

RETAINER

SPRING

FIG. 6

INSTALL AUGER CONTROL ROD (See Figs. 5 and 6)

1. Retrieve vinyl sleeve and spring from bag of parts and

retrieve the auger control rod from carton chute tray.

Slide straight rod end through the small hole in the

vinyl sleeve. Hook spring in hole in rod end.

2. Hook end of spring into control arm with loop opening

up as shown. (See Fig. 5)

3. With top end of rod positioned under right side of control

panel, push down on rod and insert end of rod into hole

in auger control bracket. Secure with retainer spring.

AUGER

CONTROL

ROD

CONTROL

ARM

VINYL

SLEEVE

LOOP

OPENING

UP

FIG. 5