UPS5000-E-(40 kVA-320 kVA)

User Manual

3 Installation

Issue 10 (2015-09-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

63

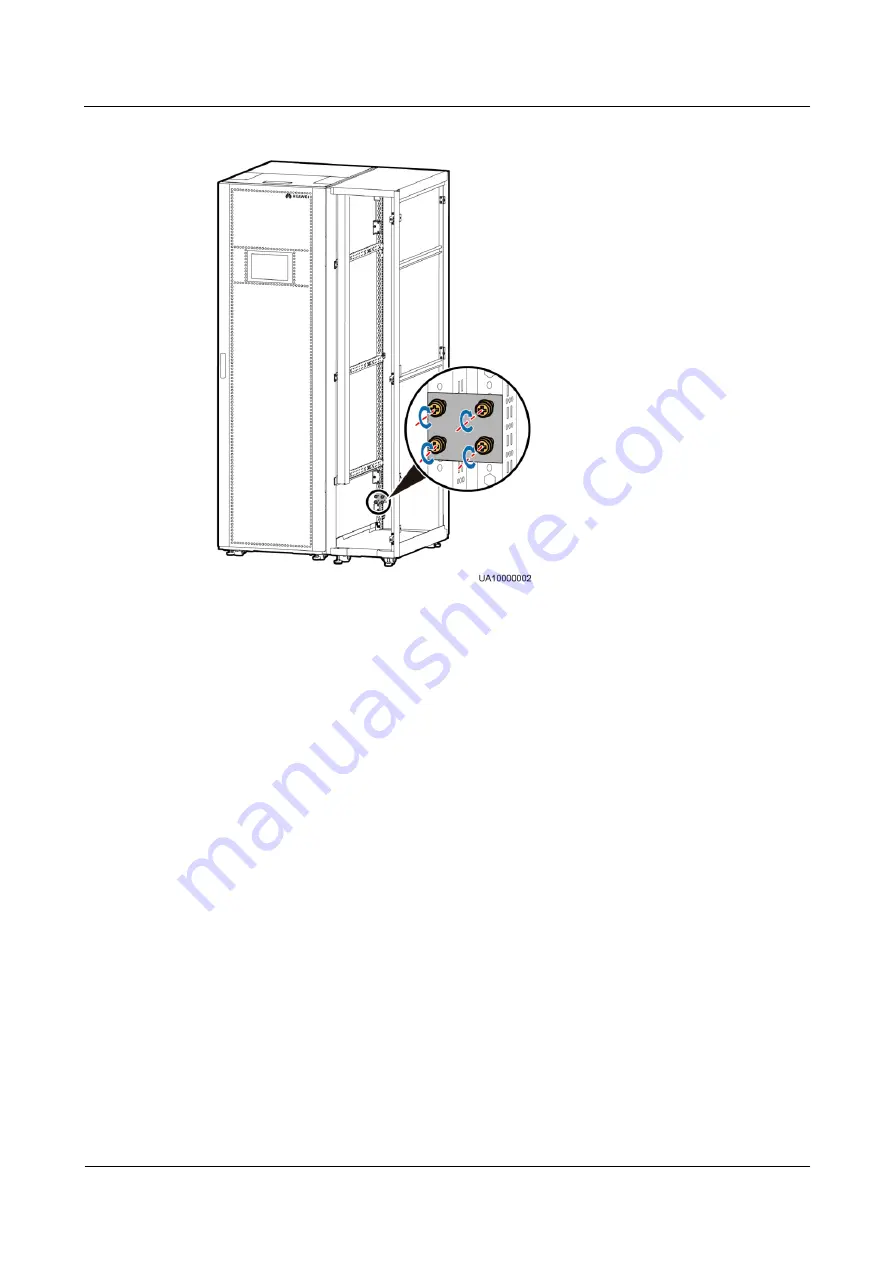

Figure 3-28

Installing parallel busbar

Step 7

Connect power cables to the UPS through the top entry cabinet, as shown in