Cabling 48

Numerous configurations are possible. This section offers two possible configurations. For more

information, see "USB support and functionality (on page

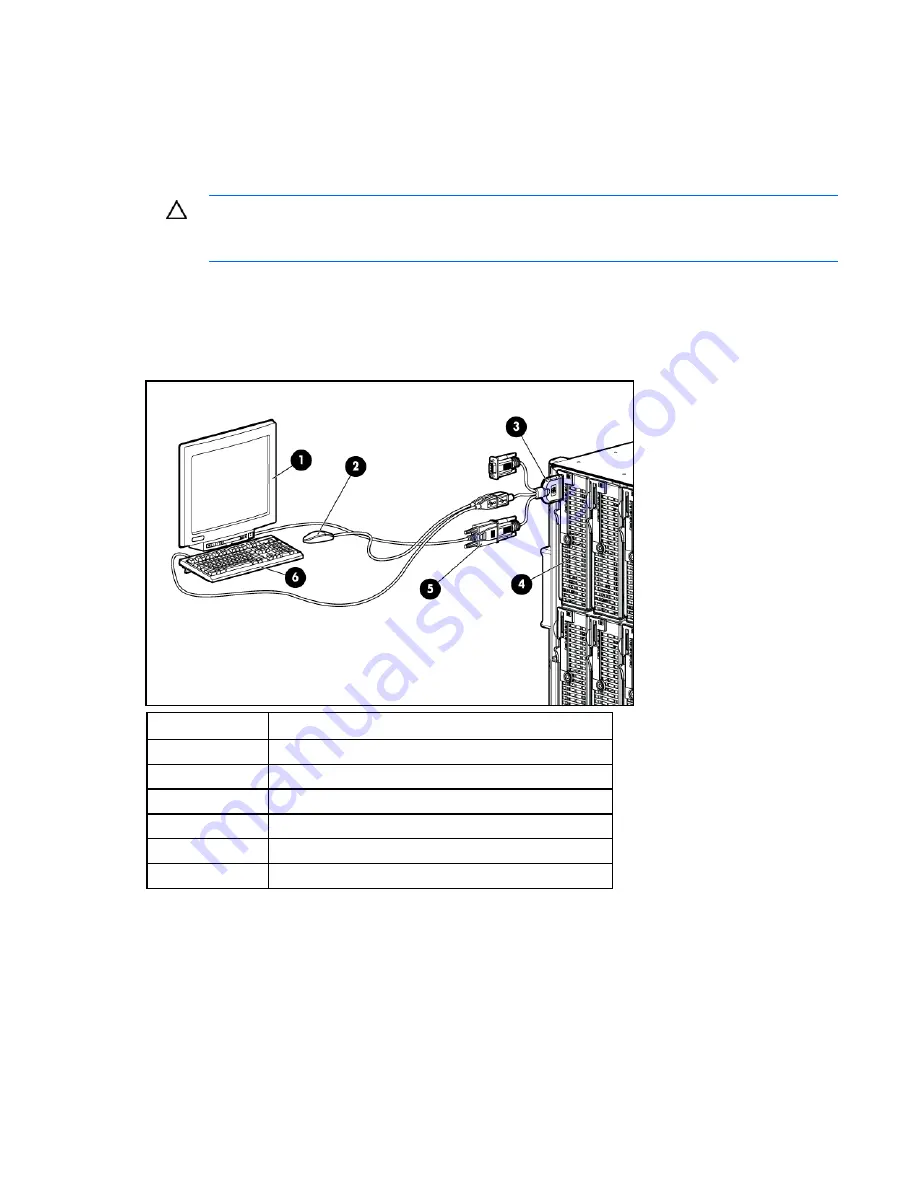

Accessing a server blade with local KVM

For this configuration, a USB hub is not necessary. To connect additional devices, use a USB hub.

CAUTION:

Before disconnecting the SUV cable from the connector, always squeeze the

release buttons on the sides of the connector. Failure to do so can result in damage to the

equipment.

1.

Connect the SUV cable to the server blade.

2.

Connect the video connector to a monitor.

3.

Connect a USB mouse to one USB connector.

4.

Connect a USB keyboard to the second USB connector.

Item Description

1 Monitor

2 USB

mouse

3

HP c-Class Blade SUV Cable

4 Server

blade

5 Video

connector

6 USB

keyboard

Accessing a server blade with local media devices

Use the following configuration when configuring a server blade or loading software updates and

patches from a USB CD/DVD-ROM or a USB diskette.

Use a USB hub when connecting a USB diskette drive and/or USB CD-ROM drive to the server blade. The

USB hub provides additional connections.

1.

Connect the SUV cable to the server blade.

Summary of Contents for ProLiant BL360 G5

Page 12: ...Customer self repair 12 ...

Page 13: ...Customer self repair 13 ...

Page 14: ...Customer self repair 14 ...

Page 15: ...Customer self repair 15 ...