Lift / lower

¾

Lift or lower the coulter until the cylinders on

all segments rest against the stop position.

At this the individual sections of the machine

move in random sequence.

¾

Switch the control unit to floating position.

Adjusting the working

depth

WARNING

Hydraulic movements can lead to severe ac-

cidents and injuries.

Ask people to leave the zone of the tines before

operating the hydraulic system.

The working depth is determined by the pre-load

on the hydraulic cylinders and the depth setting

on the rollers.

The two settings must correspond to each other.

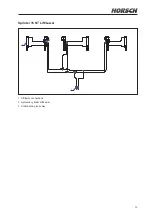

Aluminium clips

The aluminium clips are plugged over the piston

rods of hydraulic cylinders. They limit the retrac-

tion of the piston rod.

Different Aluminium Clips

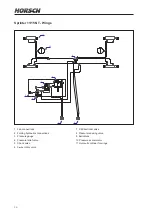

Adjusting the pre-load

The three rows of tines are each connected to

a hydraulic cylinder via push rods. The tines are

thereby pre-loaded hydraulically on the rubber

elements.

a

b

a

Bracket for aluminium clips not needed (below the

cylinder)

b

Push rod

The fewer aluminium clips are placed on the

hydraulic cylinders, the more the tines are pre-

loaded on lowering.

¾

Lifting the tines.

¾

Remove the clips from or place them on the

hydraulic cylinders.

¾

Check the adjustment of the pre-load

NOTE

¾

Insert the clips in the guide with the spring

pointing up so that the clips cannot twist or

fall out.

¾

Place the same number and colour of clips

on all hydraulic cylinders.

Pre-load too

high

:

¾

The rollers may sink especially into loose soil

or be unnecessarily loaded.

•

The rear support wheels are lifted temporarily

or constantly.

Pre-load too

low

:

•

The placing depth is not ensured. The tine is

not kept steady in the soil.

•

The seed is not sufficiently covered or pressed

down.

33