Lock-N-Load

®

AP

™

Primer Pocket Swage Tool

ASSEMBLY & PREPARATION

Before using your new swage tool,

disassemble and carefully clean the dies,

removing the rust preventative. DO NOT

disassemble the swage punch assembly

(1) as it comes pre-set from the factory.

Any commercial solvent or cleaner, like

Hornady ONE SHOT

®

Gun Cleaner and

Dry Lube, will suffice. Reassemble the

swage die after cleaning.

Cartridge cases should be de-primed and

inspected. Discard those with cracks,

splits, or other visible defects. Make sure

case necks are round. You may need

to run an expander through them or full

length size the cases before swaging.

Primer pockets should be clean.

IMPORTANT: Sort cases by manufacturer

and lot number, if possible. Different

brands have varying web thicknesses,

which can cause swage variation.

INSTRUCTIONS

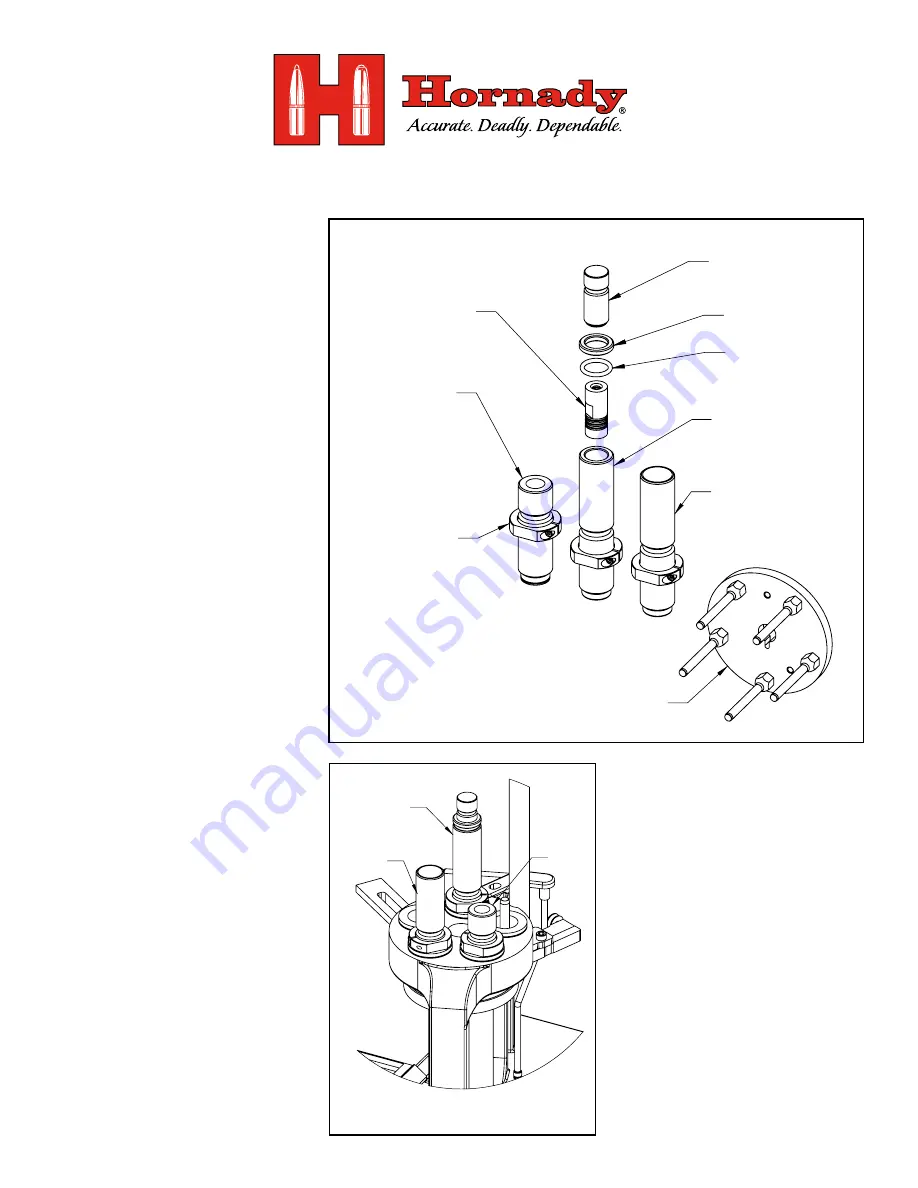

Install swage plate assembly (5) onto

your Lock-N-Load

®

AP™. You will not

need a case retainer spring.

Raise the press ram to the top of its

stroke and thread the swage die (7) into

station 1

(Fig. A)

until it makes contact

with the swage plate assembly. Back the

swage die off a half turn and tighten the

Sure-Loc

™

lock ring (3).

Thread the swage stripper die (2) into

station 3

(Fig. A)

until it makes contact

with the swage plate. Tighten the

Sure-Loc

™

lock ring.

Thread the swage alignment die (6) into

station 4

(Fig. A)

until it makes contact

with the swage plate. Tighten the

Sure-Loc

™

lock ring.

NOTE: The swage stripper die and

swage alignment die must be in contact

with the swage plate assembly while

the press ram is at the top of the stroke

to assure proper function of the swage

die without damaging the press.

8. O-RING

10. SWAGE

ADJUST

SCREW

9. LOCK RING

5. SWAGE

PLATE

ASSEMBLY

6. SWAGE

ALIGNMENT

DIE

7. SWAGE DIE

2. SWAGE

STRIPPER

DIE

3. SURE-LOC

™

LOCK RING

1. SWAGE

PUNCH

ASSEMBLY

PARTS

SWAGE DIE

ASSEMBLY

SWAGE

ALIGNMENT

DIE

SWAGE

STRIPPER

DIE

Figure A

Insert a sorted case into the swage

alignment die mouth first. Lower the

press ram. The case will feed onto the

swage plate support stem.

With the swage adjust screw (10)

backed out of the swage die, cycle the

press until the inserted case enters the

swage die.

Thread the swage adjust screw down

until you feel resistance. Lower the

press ram about 1-inch and thread the

swage adjust screw down half a turn.

Raise the press ram. You should start

to feel the resistance when raising

the press ram. At this point, the primer

pocket crimp is starting to be swaged.

Adjustment for the proper amount

of swage is done by trial and error.

(OVER)