6 FUNCTIONALITIES

66

6.6.5

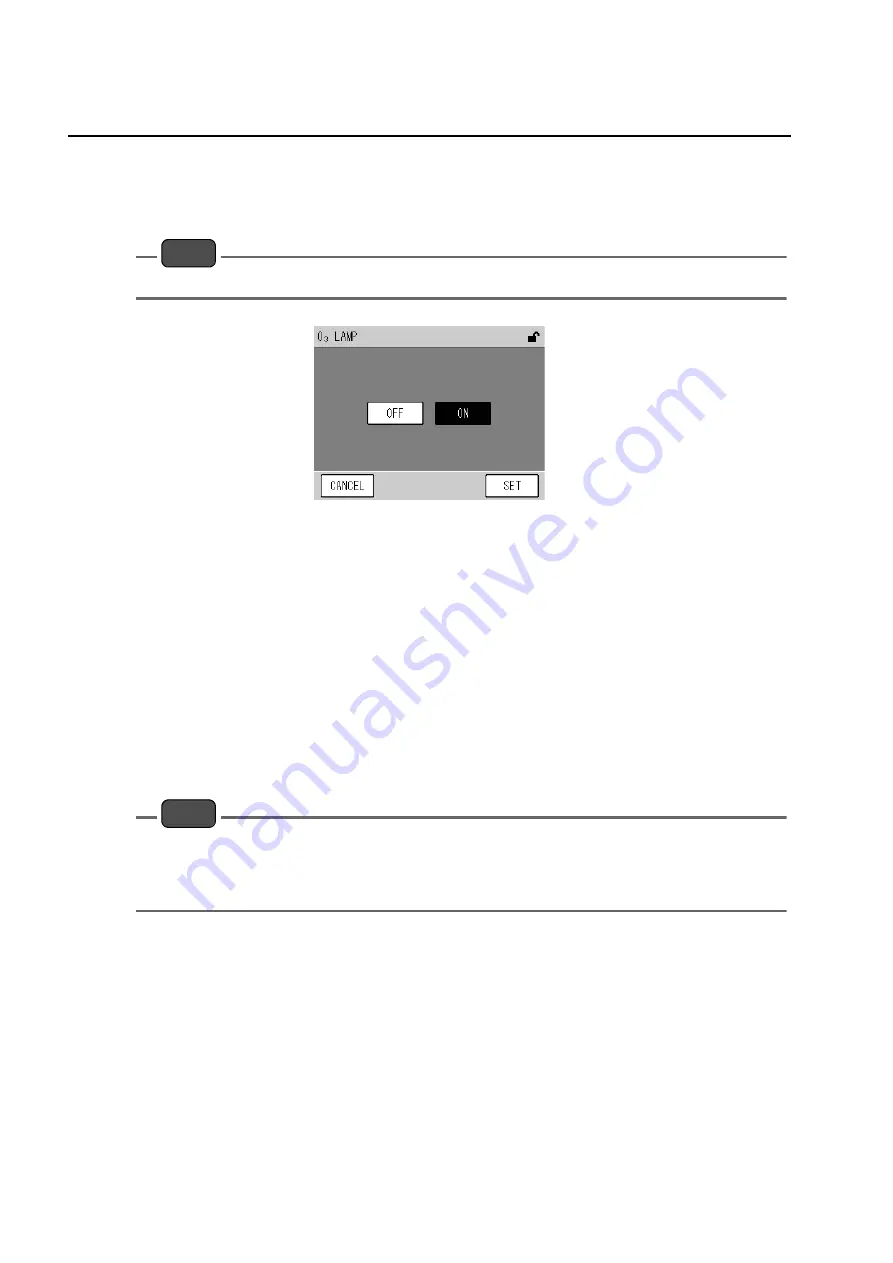

Turning ON/OFF the ozone lamp

Press the [O

3

LAMP] button on the MENU/SYSTEM screen. The O

3

LAMP screen will be

displayed.

This screen allows you to manually turn ON/OFF the ozone lamp.

Note

When the power is turned ON, the ozone lamp will be automatically turned ON.

Fig. 83 O

3

LAMP screen

The buttons allow you to perform the following operations.

The keys allow you to perform the following operations.

Note

If the flow rate error, pressure error, or converter temperature error occurs, the ozone lamp will not be

turned ON. Even if O

3

Lamp ON is displayed on the O

3

LAMP screen or MEAS. screen, the ozone lamp

will be automatically turned OFF so far as the above error persists (Automatic O

3

lamp OFF function).

Once the error is eliminated, the O

3

lamp will be automatically turned ON.

[ON]:

Selects starting generation of ozone.

Subsequently pressing the [SET] key will turn ON the ozone lamp and start

generating ozone.

[OFF]:

Selects stopping generation of ozone.

Subsequently pressing the [SET] key will turn OFF the ozone lamp and stops

generating ozone.

[CANCEL]: Cancels the operation and returns to the MENU/SYSTEM screen.

[SET]:

Executes the operation and returns to the MENU/SYSTEM screen.

Summary of Contents for APNA-370

Page 1: ...Ambient NOx monitor APNA 370 Operation Manual eng CODE GZ9100497232L ...

Page 8: ......

Page 12: ......

Page 108: ......

Page 110: ......

Page 111: ......

Page 113: ...2 Miyanohigashi Kisshoin Minami ku Kyoto 601 8510 Japan http www horiba com ...