R8182D,E,F,H,J COMBINATION PROTECTORELAY™ AND HYDRONIC HEATING CONTROLS

68-0105—2

14

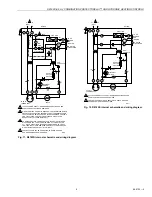

Fig. 20. R8182F Aquastat

®

limit switching.

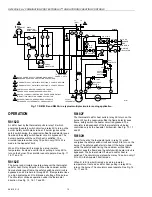

STARTUP AND CHECKOUT

WARNING

Explosion Hazard.

Can cause severe injury, death or property

damage.

This product is intended for use only in systems with a

pressure relief valve.

Because heating systems differ, the correct temperature

setting for one system may not be correct for another. Follow

the boiler manufacturers recommendations for proper

selection of settings.

High Limit Setting—All Models

The high limit opens and turns off the burner when the water

temperature reaches the setpoint. The high limit automatically

resets after the water temperature drops past the setpoint and

through the 10°F (6°C) [15°F (8°C) with R8182E,J] differential.

Set the indicator at the desired shutoff temperature.

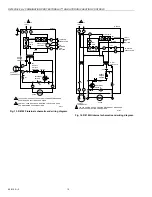

Low Limit/Circulator Setting—D And H

Models

On a temperature rise, with the adjustable differential at the

minimum setting of 10°F (6°C), the burner circuit (R-B) breaks

and the circulator circuit (R-W) makes at the low limit setpoint.

See Fig. 19. On a temperature drop of 10°F (6°C) below the

setpoint, the R-B circuit makes and the R-W circuit breaks.

At any differential setting greater than 10°F (6°C), the R-B

make temperature and R-W break temperature remains the

same— setting minus 10°F (6°C). The R-B break and R-W

make temperature are the setpoint temperature plus the

difference between the differential setting and 10°F (6°C).

EXAMPLE: Setpoint of 140°F (60°C); differential set at 25°F

(14°C). On a temperature rise, R-B breaks and R-W makes at

155°F (68°C). On a temperature fall, R-B makes and R-W

breaks at 130°F (54°C).

Set the low limit indicator at the minimum temperature

recommended for domestic hot water supply. This setting

must be at least 20°F (11°C) below the high limit setting to

prevent one switch from locking out the other.

Set the differential the desired number of degrees.

Circulator Setting—F Models

Set the circulator indicator at the minimum water temperature

recommended for hydronic heating comfort.

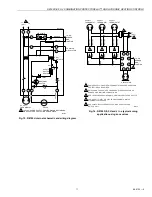

Setting Stops (R8182D,H TRADELINE®)

Part no. 126580 Setting Stops can be installed on the low and

high limit adjusting knobs to prevent turning the knobs beyond

a predetermined point. To install the setting stops, proceed as

follows:

IMPORTANT

Once the setting stops are in place, they cannot be

replaced. If they must be removed, cut off with

cutters—do not twist off.

1.

On low limit knob, turn the knob to the setting that is to

be established as the limit.

2.

Place the setting stop over the knob so that the arm of

the setting stop (after the stop is pressed into place)

strikes projection A and prevents turning the knob

beyond the chosen limit setting. See Fig. 21.

3.

Press the setting stop tightly onto the knob so its inner

teeth securely engage the knob.

4.

Turn knob back and forth several times to make sure

stop functions properly.

5.

Repeat steps 1 to 4 for the high limit knob.

After settings are made, replace the cover.

CIRCULATOR

SETTING

HIGH LIMIT

SETTING

R-B BREAKS ON

TEMPERATURE RISE.

BURNER TURNS OFF.

R-B MAKES ON

TEMPERATURE FALL.

BURNER OPERATES

ON CALL FOR HEAT.

R-B BREAKS ON

TEMPERATURE FALL.

CIRCULATOR TURNS OFF.

R-W MAKES ON

TEMPERATURE RISE.

CIRCULATOR TURNS ON.

110

°

F (43

°

C)

240

°

F (116

°

C)

M1509

10

°

F (6

°

C)

DIFFERENTIAL

10

°

F (6

°

C)

DIFFERENTIAL

Summary of Contents for R8182D

Page 18: ...68 0105 2 18 ...

Page 19: ...19 68 0105 2 ...