Removing/Cleaning/Replacing Sensor Modules

WARNING!

Do not replace sensors in hazardous locations.

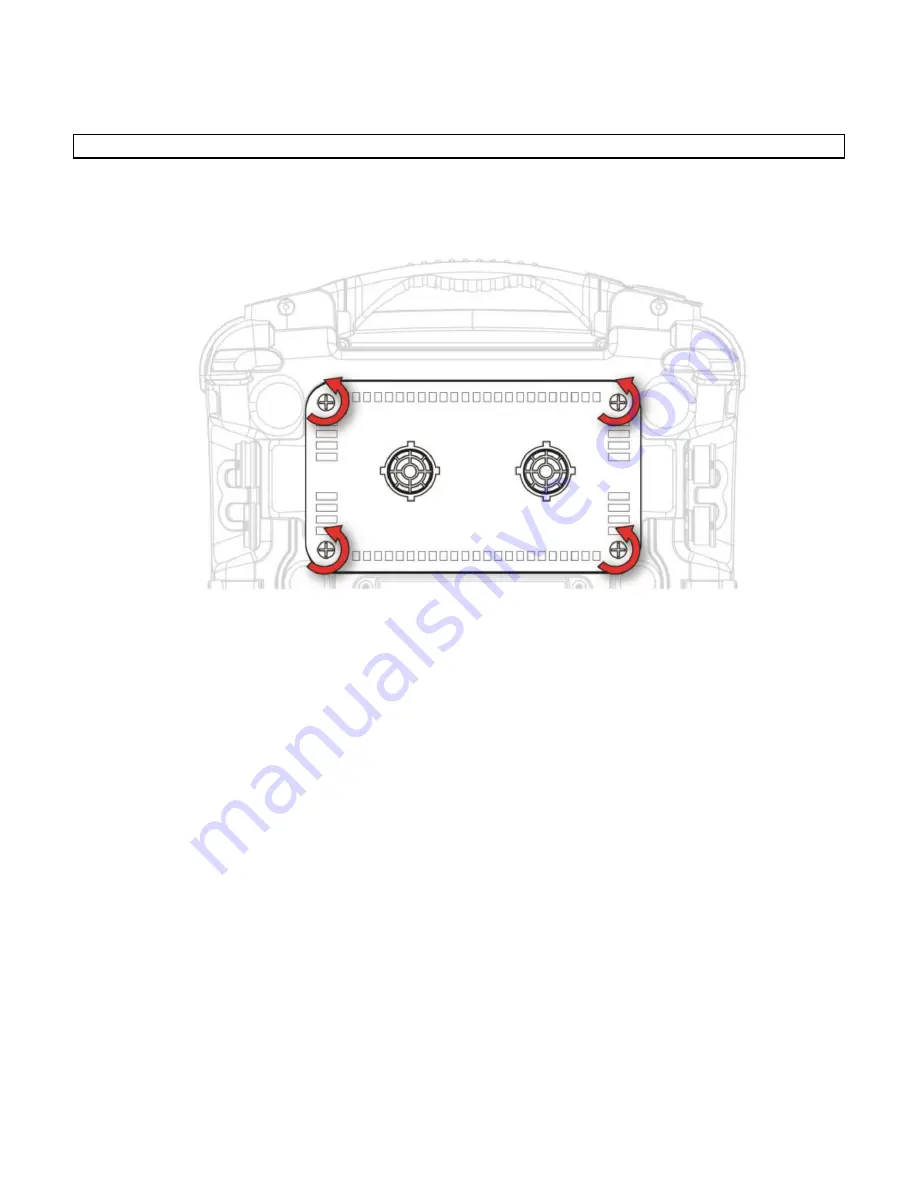

All sensors are located inside the sensor compartment in the upper half of the AreaRAE

Plus/Pro. They are accessed by removing the cover that is held on by four screws.

1.

Turn off the instrument.

2.

Remove the four screws holding the sensor compartment.

3.

Remove the cover. The sensors are plugged into the slots.

4.

Gently lift out the desired sensor module with your fingers.

5.

Install the replacement sensor. It can only go into its slot one way. The connector inside

the AreaRAE Plus/Pro and the indexing guides are good visual indicators of how to set

the sensor into position. Make sure the indexing keys are aligned and press the sensor

into place to ensure it is seated firmly. Note that the sensors are also in different sizes,

and one size cannot be substituted for another.

AreaRAE

101

User Manual

Summary of Contents for AreaRAE Plus

Page 1: ...AreaRAE WIRELESS MULTI GAS MULTI THREAT DETECTOR ...

Page 2: ......

Page 17: ...AreaRAE 16 User Manual ...

Page 22: ...Temperature Relative humidity AreaRAE 21 User Manual ...

Page 34: ...The instrument should wake up and begin monitoring immediately AreaRAE 33 User Manual ...

Page 145: ...Rev C September 2021 User Manual P N W01 4001 000 ...