Precision Platform 4022 Scanner

Scanner Maintenance

10/18/07

p/n:

6510020208

9-6

•

Removing and replacing beam cover sections

•

Replacing beam cover seals (if installed)

•

Eliminating condensation on the beam covers

9.2.5.1.

Checking air flow

Check the scanner air purge daily (if it is used) by opening the cable end

support doors and checking for air flow at the top of the end support. If

there is an air flow meter (anemometer) available, use it to record the flow

after new filters have been installed. Use the readings to compare with

later measurements to determine if the flow is being reduced. If the flow is

reduced by 25%, check the inlet filters, blowers, or duct damper settings.

9.2.5.2.

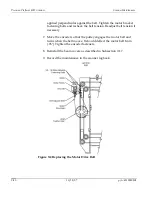

Checking air inlet filters

Check the air inlet filters weekly. Subsection 9.2.5.1 describes a method for

checking the flow through the filters to determine if they need replacing.

Also, visual inspection can determine if they need replacement. A filter

covered with dust needs to be replaced. The frequency of replacement is

determined by the air quality at the air inlet. Relocating the air inlet to a

cleaner location in the mill reduces the number of times the filters need to

be replaced. Filters can be reused several times by removing them and

blowing compressed air through the clean side of the filter. If small holes

are visible, the filter needs to be replaced.

9.3. Power tracks

9.3.1. Maintaining the power tracks

•

Blow out any debris using pressurized air

•

Check hose and cable clearance

•

Check hose, cables, and links for wear

•

Check service loops

•

Check cable clamps

Summary of Contents for 4022

Page 1: ...Precision Platform 4022 Scanner System Manual 6510020208 ...

Page 2: ......

Page 3: ...Precision Platform 4022 Scanner October 2007 ...

Page 22: ......

Page 72: ......

Page 94: ......

Page 126: ......

Page 162: ......

Page 170: ......

Page 234: ......

Page 239: ...Glossary p n 6510020208 10 18 07 11 5 VIO Virtual Input Output ...