3

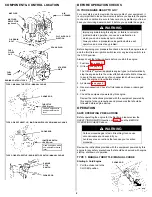

2. Move the throttle lever (gray)

away from the SLOW

position, about 1/3 of the way

toward the FAST position.

Some engine applications

use a remotely-mounted

throttle control rather than the

engine-mounted throttle lever

shown here.

3. Pull the starter grip lightly until

resistance is felt, then pull

briskly.

NOTICE

Do not allow the starter grip to

snap back against the engine.

Return it gently to prevent

damage to the starter.

4. If the choke rod was pulled to the CLOSED position to start the

engine, push it to the OPEN position as soon as the engine warms

up enough to run smoothly.

Throttle Setting

Position the throttle control lever

(gray) for the desired engine

speed. For best engine

performance, it is recommended

the engine be operated with the

throttle in the FAST (or high)

position.

Starting a Warm Engine

If the engine has run out of fuel, pull the choke rod to the CLOSED

position after refueling. If the engine has not run out of fuel, leave the

choke rod in the OPEN position.

1. Place the throttle lever in the FAST position.

2. Pull the starter grip lightly until you feel resistance, then pull briskly.

Stopping The Engine

1. Move the throttle lever (gray)

to the SLOW position.

2. Allow the engine to idle for a

few seconds, then move the

throttle lever to the STOP

position.

TYPE 2: FIXED THROTTLE / IGNITION SWITCH LEVER /

MANUAL CHOKE

Starting A Cold Engine

1. Pull the choke rod to the

CLOSED position.

2. Move the ignition switch lever

(red) to the ON position.

Some engine applications use

a remotely-mounted ignition

switch rather than the engine-

mounted ignition switch lever

shown here.

3. Pull the starter grip lightly until

resistance is felt, then pull

briskly.

NOTICE

Do not allow the starter grip to

snap back against the engine.

Return it gently to prevent

damage to the starter.

4. If the choke rod was pulled to the CLOSED position to start the

engine, push it to the OPEN position as soon as the engine warms

up enough to run smoothly.

5. The engine speed is preset on this type.

Starting a Warm Engine

If the engine has run out of fuel, pull the choke rod to the CLOSED

position after refueling. If the engine has not run out of fuel, leave the

choke rod in the OPEN position.

1. Pull the starter grip lightly until you feel resistance, then pull briskly.

2. If the choke was pulled to the CLOSED position to start, push it to

the OPEN position as soon as the engine starts.

Stopping The Engine

Move the ignition switch lever

(red) to the OFF position.

SLOW

FAST

THROTTLE

LEVER (gray)

STARTER GRIP

FAST

SLOW

THROTTLE

LEVER (gray)

STOP

FAST

THROTTLE

LEVER (gray)

CHOKE ROD

IGNITION SWITCH

LEVER (red)

ON

STARTER GRIP

OFF