ENGLISH | 19

9. Troubleshooting

In order to prevent damage or serious injury while repairing machine faults, the following points must be observed:

• Only attempt to repair a fault if you have qualified personnel. This means each job must be carried out by trained

specialist personnel, for example electrical work must be performed by a trained electrician.

• Always secure the machine against an accidental restart by disconnecting it from the electric system. Lock out, tag

out, and take appropriate safety precautions.

• Always have a second person make sure the machine is switched off in an emergency.

• Secure moving parts to prevent injury.

• Independent work on the machine is at one‘s own risk and releases the manufacturer from any warranty obligation.

Afin d‘éviter tout dommage ou blessure grave lors de la réparation de la machine, les points suivants doivent être respectés :

• Ne tentez de réparer une défectuosité que si vous disposez d‘un personnel qualifié. Cela signifie que chaque travail

doit être effectué par un personnel spécialisé formé, par exemple, les travaux d’électricité doivent être effectués par

un électricien qualifié.

• Toujours sécuriser la machine contre un redémarrage accidentel en la déconnectant du système électrique. Verrouil-

lez, étiquetez et prenez les mesures de sécurité appropriées.

• Demandez toujours à une deuxième personne de s’assurer que la machine est éteinte en cas d’urgence.

• Attachez les pièces mobiles pour éviter les blessures.

• Toute intervention indépendante sur la machine se fait à ses propres risques et libère le fabricant de toute obligation

au titre de la garantie.

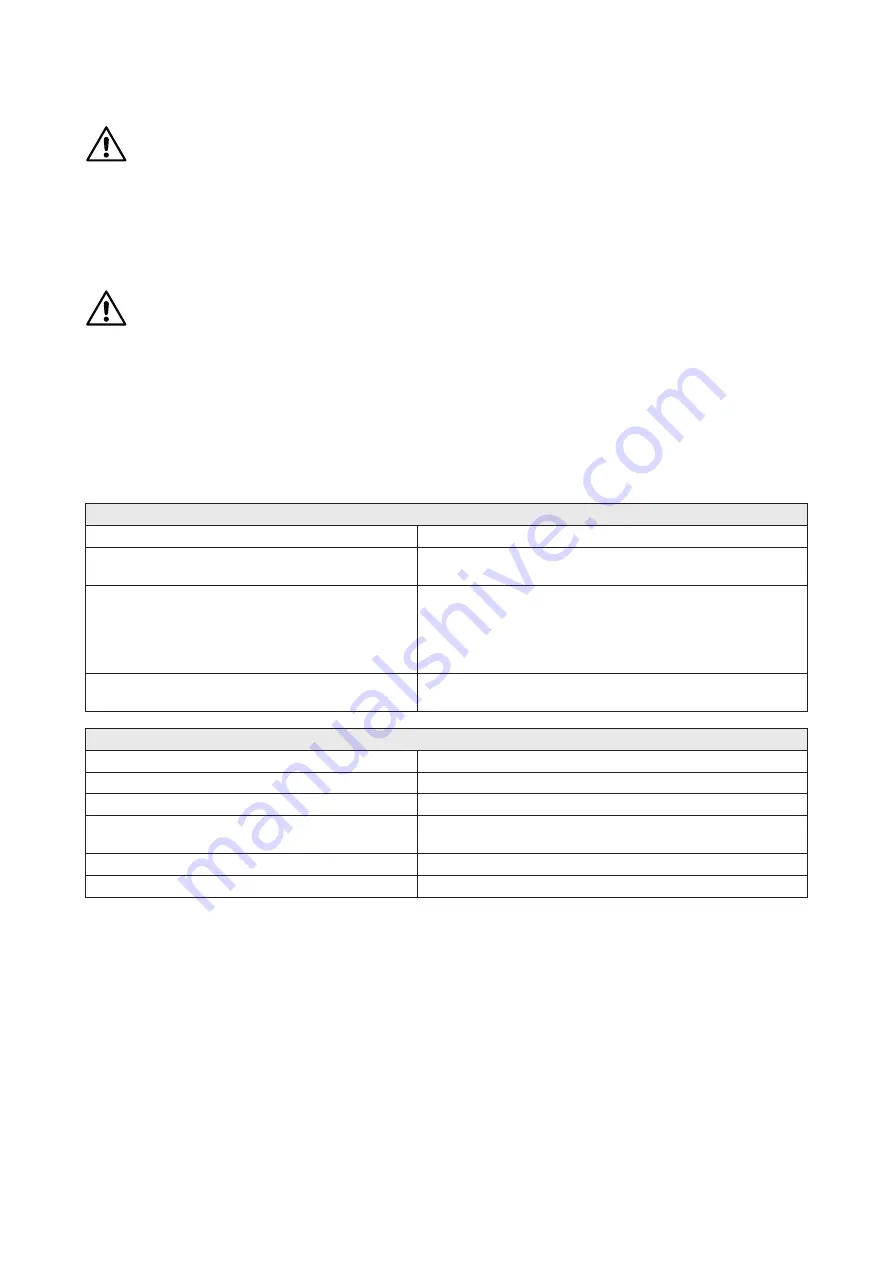

The machine will not start

Cause

Solution

Electricity supply interrupted – short circuit or ground connection in

the cable or motor windings

Have the motor and wires checked by a specialist and replaced if necessary

Fuses, the motor protection switch and/or

monitoring devices are triggered

Have a specialist inspect the connection and correct them as necessary

Have the motor protection switch adjusted according to the technical specifica-

tions, and reset monitoring equipment.

Check that the impeller/propeller runs smoothly.

Clean it or free it as necessary

The moisture sensors (option) has interrupted the power circuit

(operator-related)

See fault: Mechanical shaft seal leaks, seal chamber monitor reports fault and

switches the machine off

Machine runs but does not pump

Cause

Solution

No pumped fluid

Open the container intake or valves

Intake blocked

Clean the intake, valve, suction port or intake strainer

Impeller/propeller blocked or obstructed

Switch off the machine, secure it against being switched on again and free

the impeller/ propeller

Defective hose or piping

Replace defective parts

Intermittent operation

Check the control panel