BA_PH_436-100_EN_44-21.docx

11

3.7

Standard Equipment

•

Three-phase motor 7.5 kW (10 PS)

•

All-steel cutter block with TERSA knives

•

Electromotive height adjustment of the thicknessing table

•

Position controller with touch screen

•

Serrated table lips for noise reduction

•

Pendulum-mounted feed rollers

•

Fine-planed thicknessing table with 4 height-adjustable spindles

•

Segmented rubber infeed and outfeed roller

•

Segmented pressure beam

•

Two feed rates switchable (7 und 14 m/min)

•

Brass wedge for Tersa cutter change

•

Automatic star-delta starter

•

1 Grease gun (hollow nuzzle)

•

1 Suction nozzle 160 mm Ø

•

CE compliant and GS tested

3.8

Optional Accessories:

•

Two table rollers, steel feed rollers and rubber feed rollers (see section

•

Steel feed roller, spiral toothed instead of rubber feed roller (see section

•

Steel link feed roller, pendulum mounted, for simultaneous planing of mouldings with max.

3 mm thickness tolerance

•

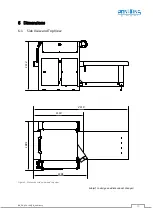

Table extension 400 mm, mounted on the machine table in the outfeed area

(see section

•

Thickness table extension (L = 1000 mm, B = 630 mm) with automatic height adjustment

(see section

•

Thickness table extension (L = 2000 mm, B = 630 mm) with automatic height adjustment

(see section

•

Frequency-controlled feed motor, infinitely variable from 3 to 24 m/min (see section

•

PANHANS 4-knives traditional cutter block with brass adjusters as well as necessary tools

(see section

•

All-steel spiral cutter block consisting of 6 spiral-shaped blade rows with improved cutting quality

due to "pulling" cut, incl. 10 spare knifes, mounting material and tools (see section

Further accessories can be found in chapter