22

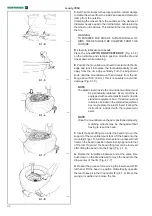

2.3.1-1

2.3.1-2

R

C

D

E

A

B

monty 3550

2.2 Air Installation

WARNING

THE AIR INSTALLATION MUST BE MADE ONLY BY

LICENSED PERSONNEL.

WARNING

EXCESSIVE AIR PRESSURE CAN SERIOUSLY INJURE

PERSONNEL AND DAMAGE THE MACHINE.

Ensure that the line pressure is within the limits required

by the machine. If the air pressure exceeds 12 bar (170

psi) it is mandatory to install a pressure regulator before

the air inlet of the machine

It is suggested that the air supply be equipped with a water

separator and air lubricator.

After ensuring all the above proceed as follows:

A.

Connect the machine to the air supply with a rubber hose

equipped with 1/4”NPT treaded junction.

WARNING

BEFORE CONNECTING THE MACHINE TO THE AIR

SUPPLY BE SURE ALL PERSONNEL ARE CLEAR OF

THE MACHINE AND THAT NOTHING IS LEFT ON THE

TURNTABLE AREA (TOOLS)

B.

Should you install any optional accessories, please

refer to the relevant instructions.

2.3 Accessories Installation

2.3.1 Installing the Kit: EAA0332G91A -

SLIDING JAW +4 INCH KIT

WARNING

BEFORE INSTALLATION, DISCONNECT THE

TIRE CHANGER FROM THE ELECTRICITY AND

COMPRESSED AIR SUPPLIES.

See

Figure 2.3.1-1

1) Remove the standard jaws (

R

), present on the tire

changer turntable.

2) Insert the +4” jaws supplied in the kit on the turntable

sliding parts and align the side holes (

A

) with the holes

(

B

) in the sliding parts.

CAUTION: SECURE THE SLIDING PARTS WITH BOTH

SCREWS IN THE HOLES PREPARED.

See

Figure 2.3.1-2

3) Insert the screws (

C

) in the side holes in the jaws, put

the washers (

D

) on the opposite side and secure with

the nuts (

E

).

NOTE

: If the holes (

B

) in the sliding parts are blocked by

dirt, clean them by MANUALLY inserting an 8 mm diameter

spiral bit in them several times.

CAUTION: AFTER INSTALLATION, THE JAWS MUST

BE EQUIDISTANT FROM THE CENTRE OF THE

TURNTABLE.