--- 14 ---

* The air passage is jammed

(with pieces of broken

piston bumper etc.).

* The feed piston chamber

contains foreign matter

such as pieces of broken

bumper etc.

Remove foreign matter.

Replace the piston bumper

with new one.

Body....Remove foreign matter

in the return air chamber.

Nose....Remove foreign

matter in the air passage and

the feed piston chamber.

8. TROUBLESHOOTING

8-1. Troubleshooting and Correction

Fault

Cause

(The mark * refers to main causes.)

Inspection method

Remedy

(1)

Nails fail to

eject.

< Nail >

The nailer is loaded with

nails not approved by

Hitachi.

The nailer is loaded with

abnormal nails (bent nails,

nail heads too large, or too

small, abnormally collated

nails, deformed sheet).

Nails or link pieces are

jammed.

Deformation and breaking

of collated nails

Check whether or not the

nailer is normally loaded with

nails approved by Hitachi.

Use specified nails.

Remove abnormal nails and

load the nailer with proper

nails.

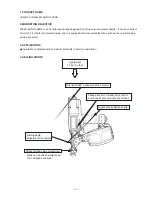

< Nail feeding section:

nose, feeder,

feed piston, etc. >

The sliding resistance of

the feed piston is too great.

The nail guide face of the

nose is abnormal

(deformed, jagged,

damaged and/or worn).

The feed spring and/or

feeder spring is abnormal

(damaged and/or fatigued).

The feeder is abnormal

(damaged and/or worn).

Remove the feed piston, and

examine the feed piston slide

surface of the nose.

Apply grease.

Polish the scratched section

with abrasive paper.

Replace parts.

Check whether or not the nail

feeding section is abnormal

(jagged, deformed, damaged

or worn).

Replace parts.

Smooth jagged areas.

Correct the deformed part.

The nose is not correctly

loaded with nails in the

groove.

Check whether or not the

nailer is correctly loaded with

nails in the specified groove.

Load the nailer with nails in

the correct position in the

nose.

Insufficient oil and/or dust

sticking in the chuck

groove's slide of the nose.

Remove dust and then apply

oil.

Air pressure is too low.

Adjust air pressure in a range

of 4.9 --- 8.3 bar (5 --- 8.5

kgf/cm

2

, 70 --- 120 psi).

Open the nail guide and inject

air to check the feeder's

action.

Summary of Contents for NV 50AG2

Page 39: ......