--- 12 ---

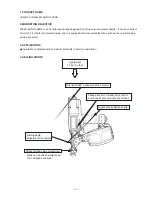

(1) Prior to nailing (Fig. 6)

1 When compressed air is supplied to the main body,

it fills the accumulator ( ////// ).

2 At the same time, the compressed air flows into the

valve piston lower chamber of the control valve

section, and pushes up the valve piston. Also, the

compressed air flows from the air supply vent,

through air passage (A), and into the head valve

upper chamber where it simultaneously pushes

down the head valve and the head valve spring to

seal the upper surface of the head valve and the

cylinder.

(2) During nailing (I) (Fig. 7)

1 When the plunger is pushed up by operating both

the pushing lever and the trigger, the compressed

air in the valve piston lower chamber is exhausted

from the lower part of the plunger. Then, the valve

piston is pushed down by the compressed air from

the accumulator ( ///// ) so that it shuts off the air

supply vent and released the exhaust valve.

2 When the exhaust valve opens, the compressed

air in the head valve chamber is exhausted into the

atmosphere through air passage (A).

3 The air pressure applied to the lower surface of the

head valve exceeds the force of the head valve

spring, and pushes up the head valve. The head

valve is pushed fully upward by the compressed

air, and seals the upper surface of the exhaust

cover and the head valve.

4 When the head valve is pushed up, the

compressed air flows rapidly into the cylinder and

pushes down the piston to drive a nail. At this

time, the compressed air flows through the cylinder

hole, into the return air chamber, through air

passage (B), and into the chamber at the left side

of the feed piston in the nail feeder section. When

the air pressure exceeds the force of the feed

spring, the feeder moves to the right.

7-2. Operation Principle

Cylinder

Head valve spring

Air passage (A)

Head valve

Accumulator

Valve piston

Control

valve

section

Air supply vent

Pushing lever

Fig. 6 Prior to nailing

Air supply vent

Fig. 7 During nailing (I)

Exhaust valve

Accumulator

Exhaust cover

Air passage (A)

Head valve spring

Head valve

Cylinder

hole

Piston

Cylinder

[Return air

chamber]

Air passage

(B)

Plunger

Trigger

Pushing lever

Valve piston

Nail feeder

section

Feed spring

Feed piston

Nail

feeder

Pushing lever

Summary of Contents for NV 50AG2

Page 39: ......