English

15

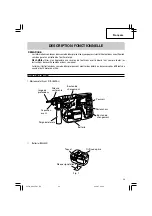

HOW TO USE

1.

Switch operation

䡬

When the switch trigger is depressed, the tool

rotates. When the switch trigger is released, the

tool stops.

䡬

The rotational speed of the rotary hammer can be

controlled by varying the amount that the switch

trigger is pulled. Speed is low when the switch

trigger is pulled slightly and increases as the switch

trigger is pulled more.

䡬

When releasing the switch trigger, the brake will

be applied for immediate stopping.

2.

Ro Striking

Align the “ ” mark with the “

” mark by

rotating the change lever to set the “Ro

Striking” mode. (Fig. 12)

(1) Mount the drill bit.

(2) Pull the trigger switch after applying the drill bit

tip to the drilling position. (Fig. 13)

(3) Pushing the rotary hammer forcibly is not

necessary at all. Pushing slightly so that drill dust

comes out gradually is just sufficient.

CAUTION:

●

When the drill bit touches an iron reinforcing rod,

the bit will stop immediately and the rotary

hammer will react to revolve. Therefore please grip

the side handle and handle tightly as shown in

Fig. 13.

Fig. 13

3.

Rotation only

Align the “ ” mark with the “ ” mark by rotating

the change lever to set the “Rotation only” mode.

(Fig. 12)

To drill a wood or metal material using the

separately sold drill chuck and chuck adaptor,

proceed as follows. Installing drill chuck and chuck

adaptor (Fig. 14):

(1) Attach the drill chuck to the chuck adaptor.

(2) The part of the SDS-plus shank is the same as the

drill bit. Therefore, refer to the item of “Mounting

the drill bit” for attaching it.

CAUTION:

●

Application of force more than necessary will not

only reducing drilling efficiency at all, but will

deteriorate the tip edge of the drill bit and reduce

the service life of the rotary hammer in addition.

●

Drill bit may snap off while withdrawing the rotary

hammer from the drilled hole. For withdrawing,

it is important to use a pushing motion.

●

Do not attempt to drill anchor holes or holes in

concrete

with the main unit in the rotation only

mode.

●

Do not attempt to use the rotary hammer in the

rotation and striking mode with the drill chuck and

chuck adaptor attached. This would seriously

shorten the service life of every components of

the machine.

4.

When driving machine screws (Fig. 15)

First, insert the bit into the socket in the end of

chuck adaptor (D).

Next, mount chuck adaptor (D) on the main unit

using procedures described in 3 (1), (2), (3), put

the tip of the bit in the slots in the head of the screw,

grasp the main unit and tighten the screw.

“ ”

mark

“

”

mark

“ ”

mark

Change

lever

Fig. 12

“ ”

mark

Part of

SDS-plus

shank

Front

cap

Grip

Fig. 14

Drill chuck

Chuck adaptor

01Eng_DH25DAL_US

9/14/07, 20:39

15