-5-

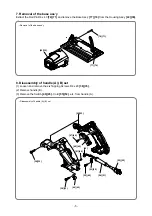

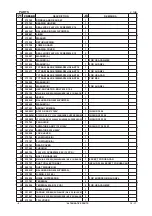

• Disassembly of handle (A).(B) set

• Removal of the base ass'y

[74]{71}

[42]{39}

[77]{74}

[38]{35}

[48]{45}

[47]{44}

[46]{43}

[51]{46}

[54]{51}

{48}

[56]{53}

[55]{52}

[53]{50}

[52]{49}

[38]{35}

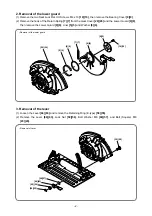

7. Removal of the base ass’y

Extract the Roll Pin D6 x 40

[74]{71}

and remove the Base Ass’y

[77]{74}

from the Housing Ass’y

[42]{39}

.

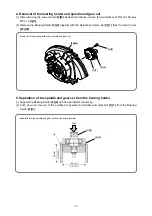

8. Disassembly of handle (A).(B) set

(1) Loosen and remove the six Tapping Screws D4 x 20

[38]{35}

.

(2) Remove handle (B).

(3) Remove the Switch

[48]{45}

, Cord

[55]{52}

, etc. from handle (A).