Preventive Maintenance

20

17730-299

ULTIMAAX

®

for Fire and Rescue Vehicles

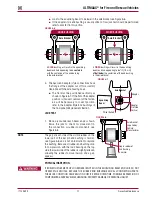

FRAME HANGER ASSEMBLY

The following points are for guidance and intended to assist personnel in determining when

frame hanger assembly maintenance is necessary .

INSPECTION

■

Inspect the frame hanger for any damage, cracks or signs of adverse or abrasive contact with

other components . Some minor wear will be evident where the progressive load spring con-

tacts the frame hanger assembly, see Figure 6-15 . If more than half the thickness of the frame

hanger plate is damaged or cracked, replace the frame hanger assembly .

■

Look for wear in the frame hanger cavity due to contact with the jounce stop, see Figure 6-15 .

If more than half the thickness of the frame hanger plate is worn or damaged, replace the

frame hanger .

■

Inspect frame hanger attaching fasteners and frame hanger assembly for signs of looseness

or movement . Retighten any loose fasteners to specified torque . Components damaged by

loose fasteners must be replaced .

FIGURE 6-15

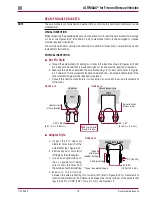

SHEAR SPRINGS

INSPECTION

Inspection of the shear spring should always be conducted with the vehicle in the

UNLOADED

condition .

■

Bent or burred edges on the rate plates extending beyond the rubber are acceptable provided

the rubber can freely expand during vehicle operation, see Figure 6-16 .

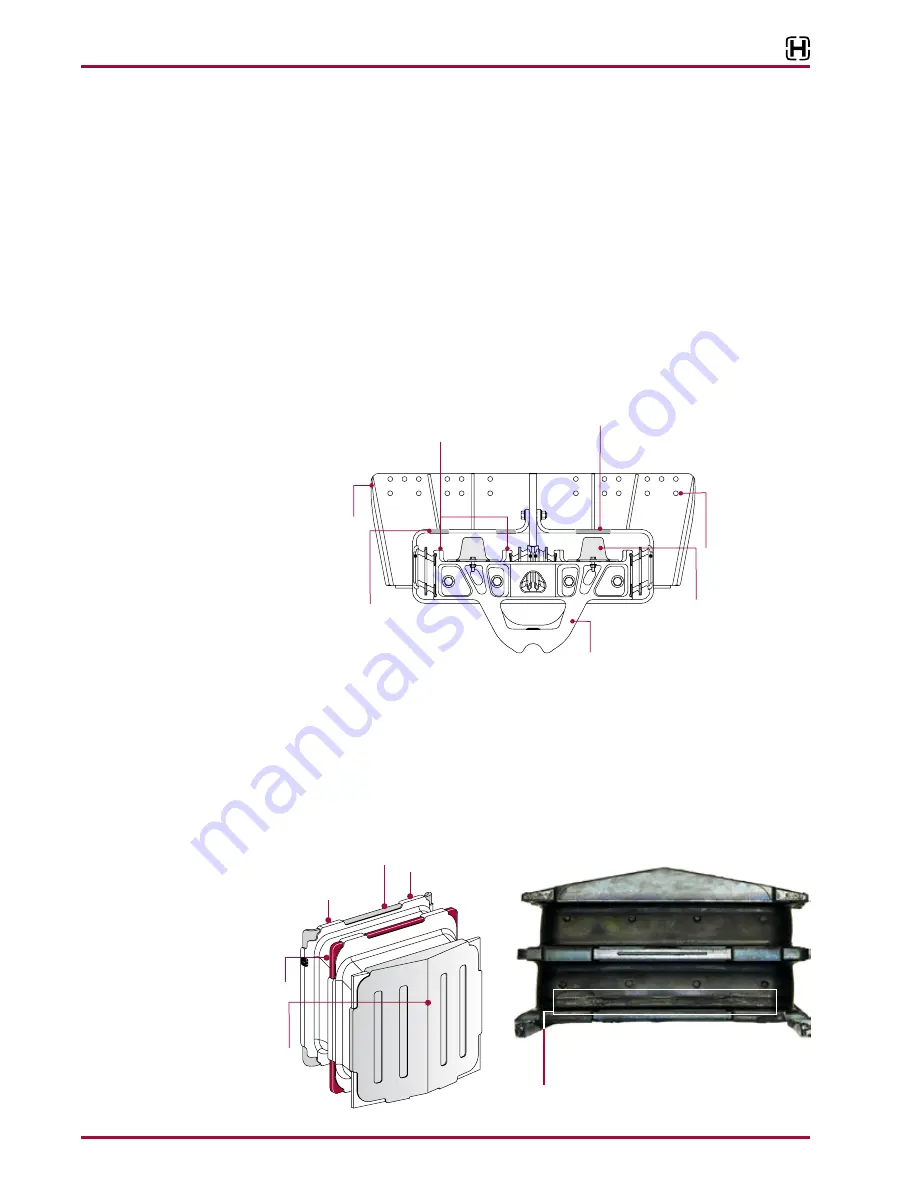

■

Creases formed by folding of the rubber surface under load are acceptable . These appear as

stripes on the surface, polished by wear or covered with tacky (sticky) rubber, see Figure 6-17 .

FIGURE 6-16

FIGURE 6-17

Frame Hanger

Progressive

Load Spring

Location of

frame hanger

attaching fasteners

Minor wear area between the

frame hanger plate and

progressive load spring

Wear area between

the frame hanger plate

and jounce stops

Jounce Stops

Saddle

Assembly

63K Shown

ULTIMAAX

Rate Plate

Shear Spring

Angled Side

Shear Spring

Flange Flat Side

Notch on Top

Notch on Top

Shear Spring

Polished Appearance

—

Creases formed by

the folding of the rubber surface under load

are acceptable.