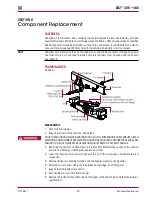

Component Replacement

38

17730-241

AR2

™

40K • 46K

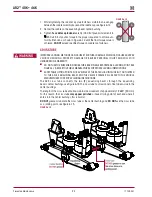

FIguRE 8‑3

13 . Tighten the saddle cap lock-

nuts to 250 ± 25 foot

pounds torque .

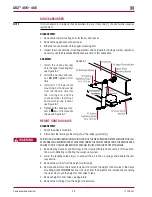

NOTE

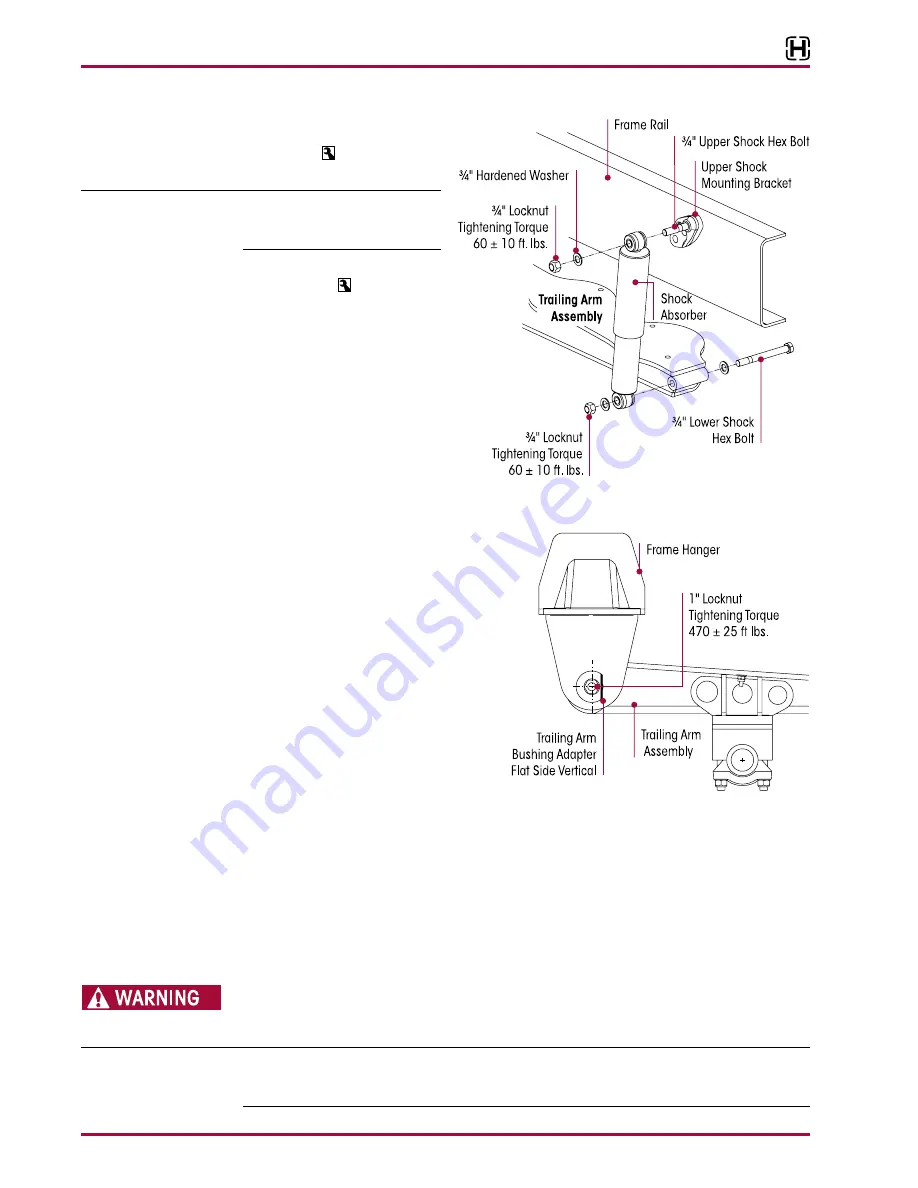

Ensure the trailing arm bushing

adapter flats are vertical, see

Figure 8-4 .

14 . Tighten the bushing adapter

locknuts to 470 ± 25 foot

pounds torque, see Figure 8-2 .

15 . See Air Spring Cautions and

Warnings in the Important

Safety Notice section of this

publication prior to deflating

or inflating the suspension

system .

16 . Connect the height control

valve linkage(s) to the height

control valve arm(s) to inflate

the suspension .

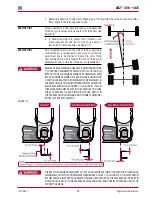

FIguRE 8‑4

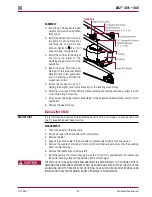

17 . Inflate the suspension slowly and verify

that the air spring bladder inflates uni-

formly without binding .

18 . Verify proper ride height, refer to Ride

Height in the Alignment & Adjustments

section of this publication .

19 . Remove the wheel chocks .

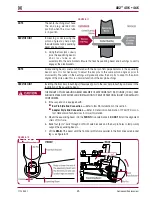

TRAILING ARM BuSHING

YOu wILL NEEd

■

A shop press with a capacity of at least 100 tons

■

Adapter set tool — (Hendrickson Part No . 66086-102) – Refer to Special Tools section of this

publication for the tools to remove and install the trailing arm bushings

■

Receiving tool — The receiving tool is a shop made tool which completely supports the beam

hub being serviced and is tall enough to receive the bushing as it is being pressed in or out,

see Special Tools section of this publication

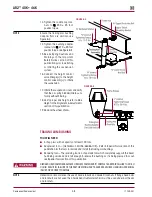

DISCARD USED FASTENERS . ALWAYS USE NEW FASTENERS TO COMPLETE A REPAIR . FAILURE TO DO SO

COULD RESULT IN FAILURE OF THE PART OR MATING PARTS, ADVERSE VEHICLE HANDLING, PERSONAL

INjURY, OR PROPERTY DAMAGE .

NOTE

Hendrickson recommends the use of Grade 8 bolts and Grade C locknuts . If flange head bolts

and locknuts are not used then hardened structural washers must be used under bolt heads

and locknuts .