Multiple-Axis Machining | The PLANE function: Tilting the working plane (option 8)

13

598

HEIDENHAIN | TNC 640 | Conversational Programming User's Manual | 10/2017

Defining the working plane with two vectors:

PLANE VECTOR

Application

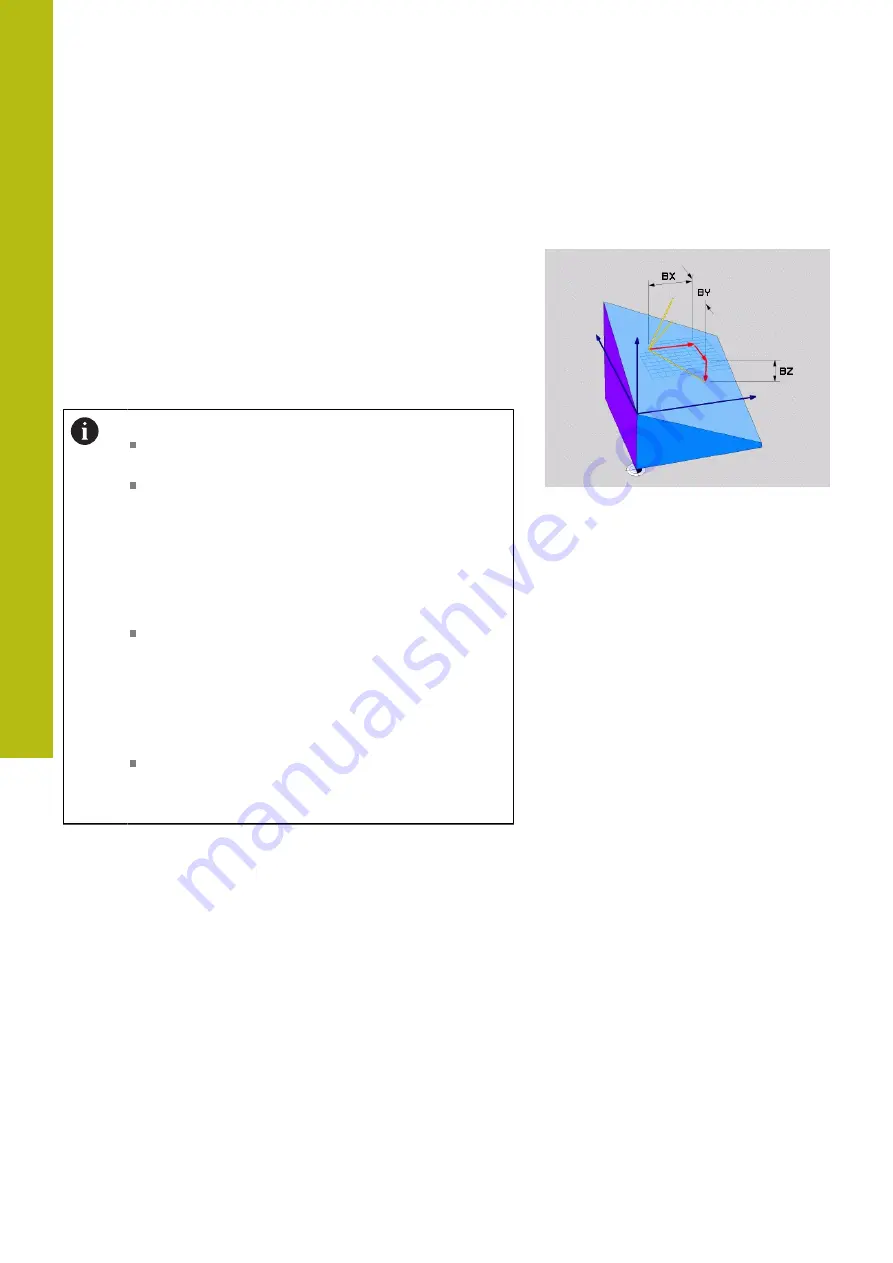

You can use the definition of a working plane via

two vectors

if

your CAD system can calculate the base vector and normal vector

of the tilted machining plane. A normalized input is not necessary.

The control internally calculates the normal, so you can enter

values between -9.999999 and +9.999999.

The base vector required for the definition of the machining plane

is defined by the components

BX,

BY

and

BZ.

The normal vector is

defined by the components

NX

,

NY

and

NZ

.

Programming notes:

The control calculates standardized vectors from the

values you enter.

The normal vector defines the slope and the

orientation of the working plane. The base vector

defines the orientation of the main axis X in the

defined working plane. To ensure that the definition

of the working plane is unambiguous, you must

program the vectors perpendicular to each other.

The machine tool builder defines how the control will

behave for vectors that are not perpendicular.

The programmed normal vector must not be too

short, e.g. all directional components having a length

of 0 or 0.0000001. In this case, the control would not

be able to determine the slope. Machining is aborted

and an error message is displayed. This behavior

is independent of the configuration of the machine

parameters.

You can select the desired positioning behavior.

Summary of Contents for TNC 640

Page 4: ......

Page 5: ...Fundamentals ...

Page 36: ...Contents 36 HEIDENHAIN TNC 640 Conversational Programming User s Manual 10 2017 ...

Page 67: ...1 First Steps with the TNC 640 ...

Page 90: ......

Page 91: ...2 Introduction ...

Page 130: ......

Page 131: ...3 Operating the Touchscreen ...

Page 144: ......

Page 145: ...4 Fundamentals File Management ...

Page 206: ......

Page 207: ...5 Programming Aids ...

Page 236: ......

Page 237: ...6 Tools ...

Page 281: ...7 Programming Contours ...

Page 333: ...8 Data Transfer from CAD Files ...

Page 355: ...9 Subprograms and Program Section Repeats ...

Page 374: ......

Page 375: ...10 Programming Q Parameters ...

Page 478: ......

Page 479: ...11 Miscellaneous Functions ...

Page 501: ...12 Special Functions ...

Page 584: ......

Page 585: ...13 Multiple Axis Machining ...

Page 650: ......

Page 651: ...14 Pallet Management ...

Page 664: ......

Page 665: ...15 Batch Process Manager ...

Page 673: ...16 Turning ...

Page 713: ...17 Manual Operation and Setup ...

Page 797: ...18 Positioning with Manual Data Input ...

Page 803: ...19 Test Run and Program Run ...

Page 843: ...20 MOD Functions ...

Page 881: ...21 Tables and Overviews ...