Fundamentals, File Management | Fundamentals

4

HEIDENHAIN | TNC 640 | Conversational Programming User's Manual | 10/2017

147

Reference systems

For the control to traverse an axis according to a defined path it

requires a

reference system

.

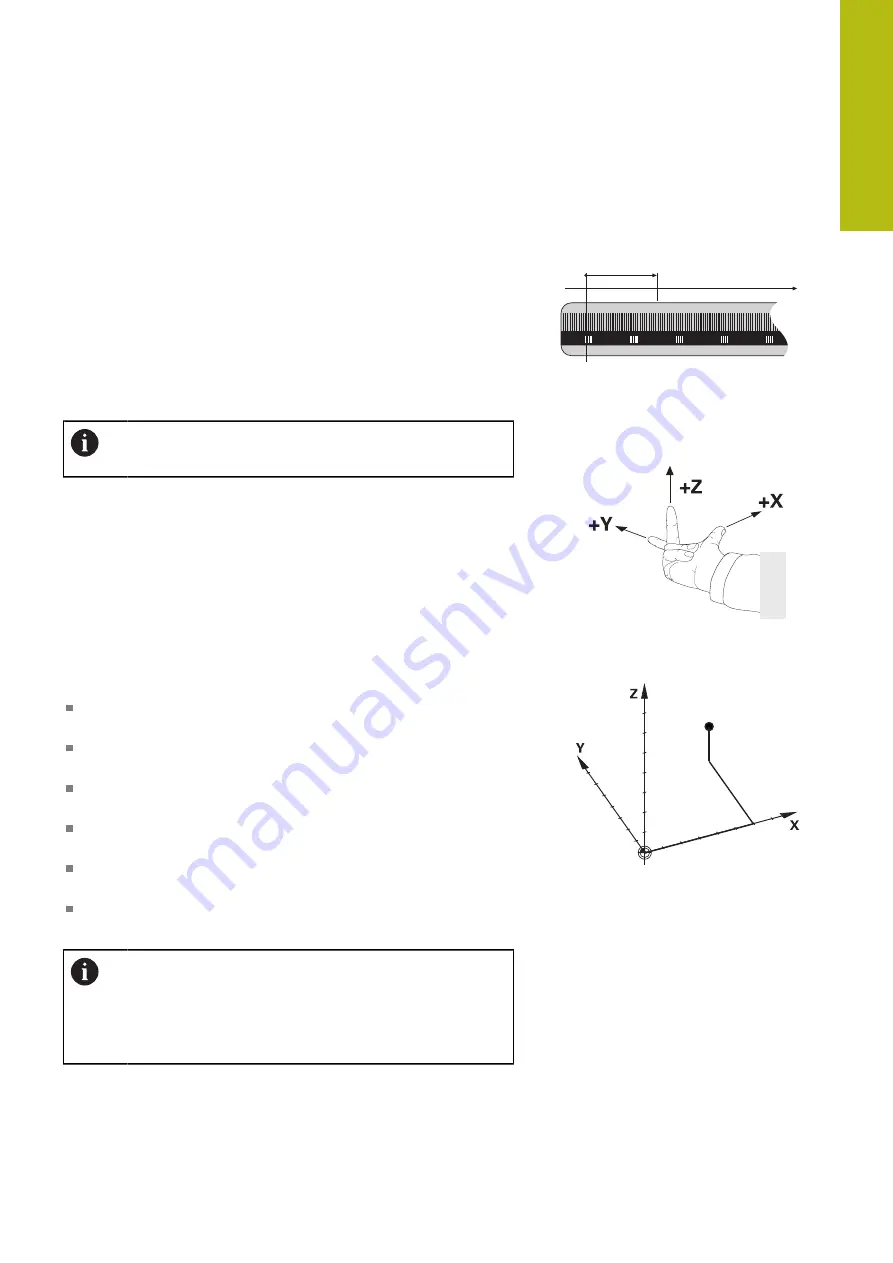

A paraxially mounted linear encoder on a machine tool serves

as a simple reference system for linear axes. The linear encoder

represents a

number ray

, a unidimensional coordinate system.

To approach a point on the

plane

, the control requires two axes and

therefore a reference system with two dimensions.

To approach a point in the

space

, the control requires three axes

and therefore a reference system with three dimensions. If these

three axes are configured perpendicular to each other this creates a

so-called

three-dimensional Cartesian coordinate system

.

According to the right-hand rule the fingertips point in

the positive directions of the three main axes.

For a point to be uniquely determined in space, a

coordinate origin

is needed in addition to the configuration of the three dimensions.

The common intersection serves as the coordinate origin in a 3-D

coordinate system. This intersection has the coordinates

X+0

,

Y+0

and

Z+0

.

The control must differentiate between various reference systems

for it to always perform a tool change at the same position for

example, or carry out a machining operation always related to the

current workpiece position.

The control differentiates between the following reference

systems:

Machine coordinate system M-CS:

M

achine

C

oordinate

S

ystem

Basic coordinate system B-CS:

B

asic

C

oordinate

S

ystem

Workpiece coordinate system W-CS:

W

orkpiece

C

oordinate

S

ystem

Working plane coordinate system WPL-CS:

W

orking

Pl

ane

C

oordinate

S

ystem

Input coordinate system I-CS:

I

nput

C

oordinate

S

ystem

Tool coordinate system T-CS:

T

ool

C

oordinate

S

ystem

All reference systems build up on each other. They are

subject to the kinematic chain of the specific machine

tool.

The machine coordinate system is the reference

system.

X

∆

Summary of Contents for TNC 640

Page 4: ......

Page 5: ...Fundamentals ...

Page 36: ...Contents 36 HEIDENHAIN TNC 640 Conversational Programming User s Manual 10 2017 ...

Page 67: ...1 First Steps with the TNC 640 ...

Page 90: ......

Page 91: ...2 Introduction ...

Page 130: ......

Page 131: ...3 Operating the Touchscreen ...

Page 144: ......

Page 145: ...4 Fundamentals File Management ...

Page 206: ......

Page 207: ...5 Programming Aids ...

Page 236: ......

Page 237: ...6 Tools ...

Page 281: ...7 Programming Contours ...

Page 333: ...8 Data Transfer from CAD Files ...

Page 355: ...9 Subprograms and Program Section Repeats ...

Page 374: ......

Page 375: ...10 Programming Q Parameters ...

Page 478: ......

Page 479: ...11 Miscellaneous Functions ...

Page 501: ...12 Special Functions ...

Page 584: ......

Page 585: ...13 Multiple Axis Machining ...

Page 650: ......

Page 651: ...14 Pallet Management ...

Page 664: ......

Page 665: ...15 Batch Process Manager ...

Page 673: ...16 Turning ...

Page 713: ...17 Manual Operation and Setup ...

Page 797: ...18 Positioning with Manual Data Input ...

Page 803: ...19 Test Run and Program Run ...

Page 843: ...20 MOD Functions ...

Page 881: ...21 Tables and Overviews ...