Test Run and Program Run | Showing the workpiece blank in the working space (option 20)

18

710

HEIDENHAIN | TNC 620 | Conversational Programming User's Manual | 10/2017

18.2 Showing the workpiece blank in the

working space (option 20)

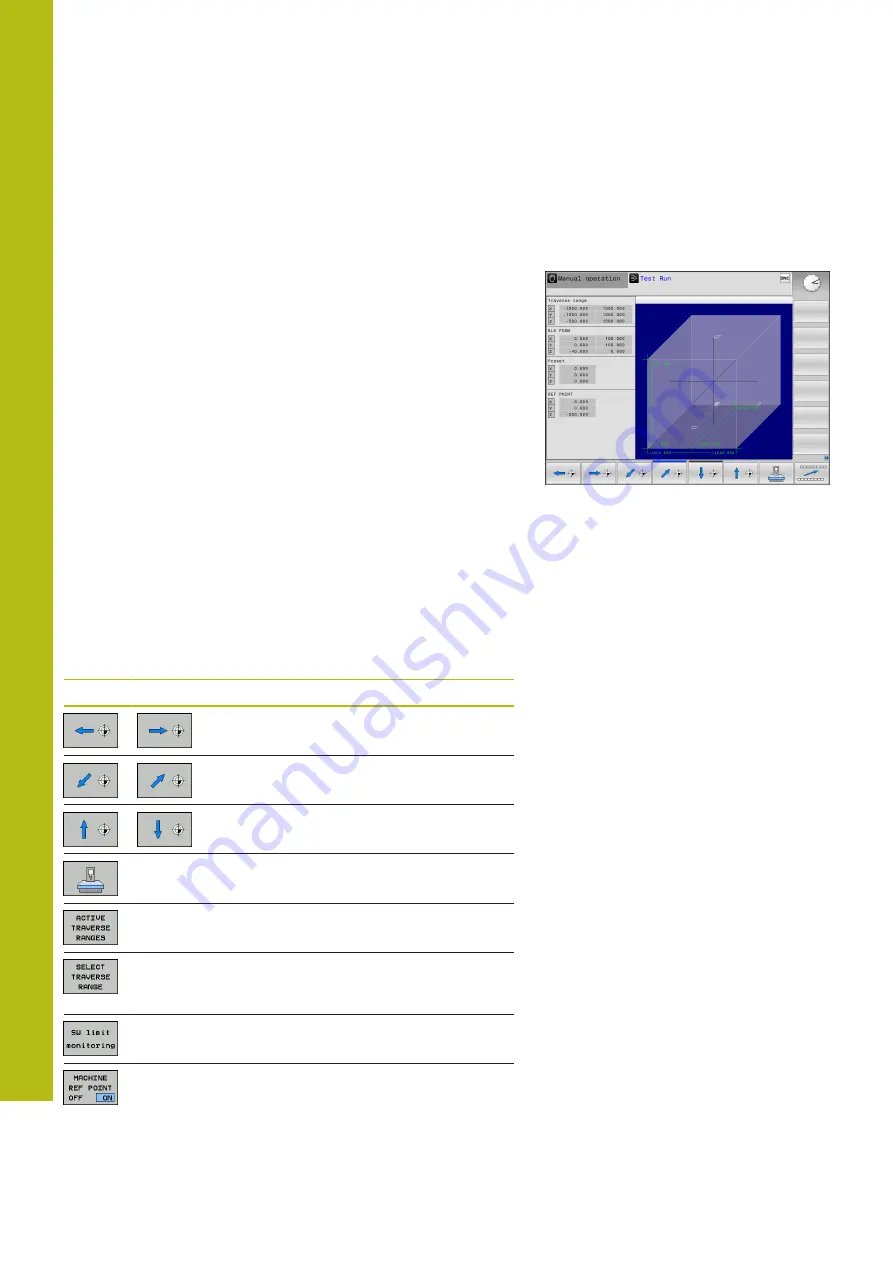

Application

In the

Test Run

operating mode, you can graphically check the

position of the workpiece blank and the preset in the working

space of the machine. The graphics show the preset that has been

set in the NC program using Cylce 247. If you have not set a preset

in the NC program, then the graphics show the active preset on the

machine.

You can active workspace monitoring in the

Test Run

operating

mode: to do so, press the

BLANK IN WORK SPACE

soft key. You can

activate or deactivate the function using the

SW limit monitoring

soft key.

A transparent cuboid represents the workpiece blank. Its

dimensions are shown in the

BLK FORM

table. The control takes

over the dimensions from the workpiece blank definition of the

selected program.

For a test run it normally does not matter where the workpiece

blank is located within the working space. If you activate

workspace monitoring, you must graphically shift the workpiece

blank so that it lies within the working space. Use the soft keys

shown in the table.

You can also activate the current preset for the

Test Run

operating

mode.

Soft keys

Function

Shift workpiece blank in positive/negative X

direction

Shift workpiece blank in positive/negative Y

direction

Shift workpiece blank in positive/negative Z

direction

Show workpiece blank referenced to the set

preset

Display the current traverse range

This shows the traverse ranges config-

ured by the machine tool builder and can be

selected accordingly.

Switch monitoring function on or off

Display machine reference point

Summary of Contents for TNC 620 E

Page 4: ......

Page 5: ...Fundamentals...

Page 34: ...Contents 34 HEIDENHAIN TNC 620 Conversational Programming User s Manual 10 2017...

Page 63: ...1 First Steps with the TNC 620...

Page 86: ......

Page 87: ...2 Introduction...

Page 123: ...3 Operating the Touchscreen...

Page 139: ...4 Fundamentals File Management...

Page 199: ...5 Programming Aids...

Page 228: ......

Page 229: ...6 Tools...

Page 271: ...7 Programming Contours...

Page 323: ...8 Data Transfer from CAD Files...

Page 344: ......

Page 345: ...9 Subprograms and Program Section Repeats...

Page 364: ......

Page 365: ...10 Programming Q Parameters...

Page 467: ...11 Miscellaneous Functions...

Page 489: ...12 Special Functions...

Page 532: ......

Page 533: ...13 Multiple Axis Machining...

Page 596: ......

Page 597: ...14 Pallet Management...

Page 610: ......

Page 611: ...15 Batch Process Manager...

Page 619: ...16 Manual Operation and Setup...

Page 693: ...17 Positioning with Manual Data Input...

Page 698: ......

Page 699: ...18 Test Run and Program Run...

Page 737: ...19 MOD Functions...

Page 774: ......

Page 775: ...20 Tables and Overviews...