Datum Setting with 3-D Touch Probe

13.8

13

TNC 320 | User's Manual

HEIDENHAIN Conversational Programming | 3/2014

447

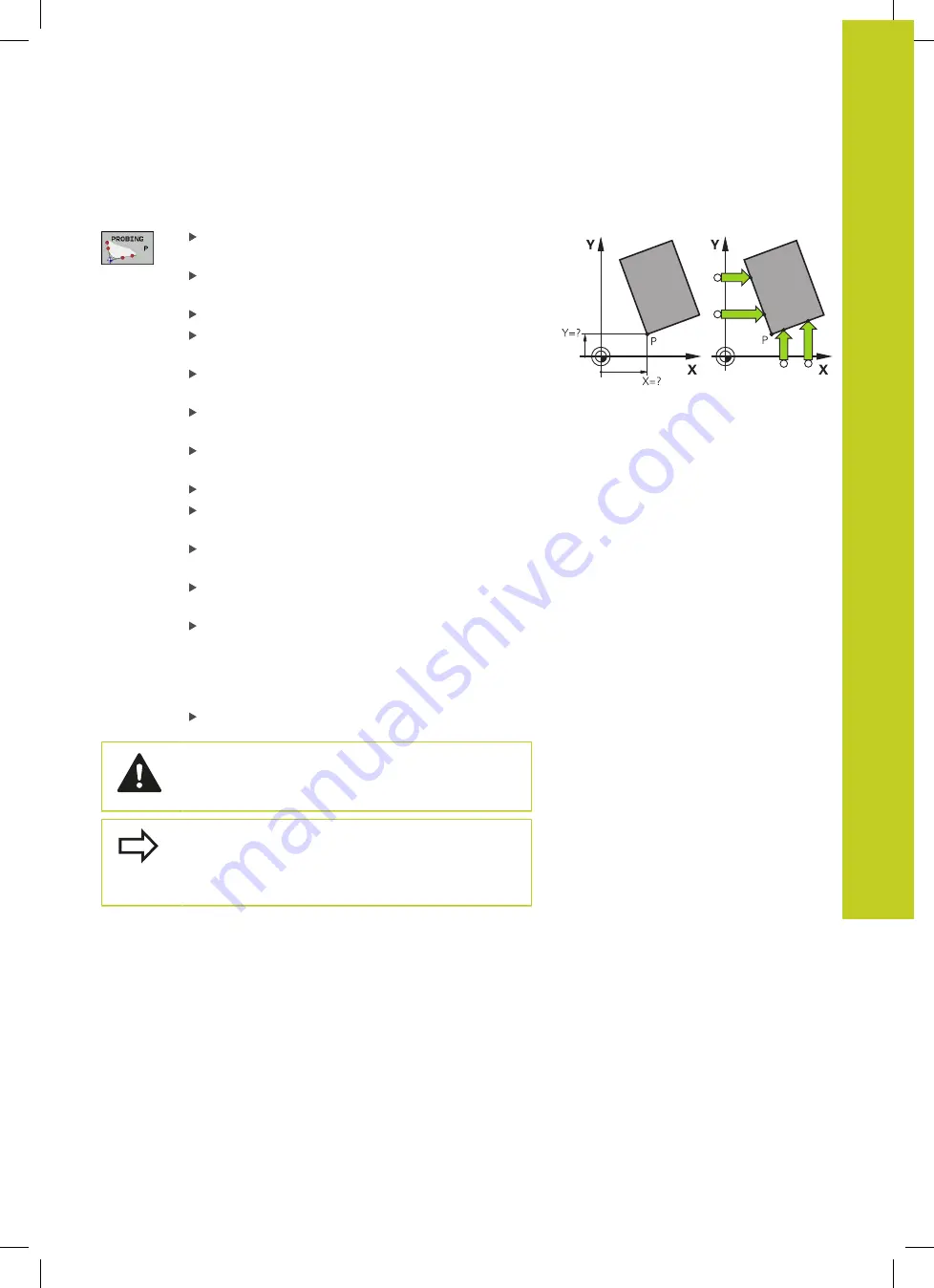

Corner as datum

Select the touch probe function: Press the

PROBING P

soft key

Position the touch probe near the first touch point

on the first workpiece edge

Select the probe direction by soft key

Start the probing procedure: Press the machine

START button

Position the touch probe near the second touch

point on the same workpiece edge

Start the probing procedure: Press the machine

START button

Position the touch probe near the first touch point

on the second workpiece edge

Select the probe direction by soft key

Start the probing procedure: Press the machine

START button

Position the touch probe near the second touch

point on the same workpiece edge

Start the probing procedure: Press the machine

START button

Datum

: Enter both datum coordinates into the

menu window, and confirm your entry with the

Set datum

soft key, or see "Writing measured

values from the touch probe cycles in the preset

table", page 437)

Exit the probing function: press the END soft key.

HEIDENHAIN only gives warranty for the function of

the probing cycles if HEIDENHAIN touch probes are

used.

You can identify the intersection of two straight lines

by holes or studs and set this as the datum. For each

straight line however, probing must only be with two

identical touch probe functions (e.g. two holes).

Summary of Contents for TNC 320

Page 4: ...Controls of the TNC 4 TNC 320 User s Manual HEIDENHAIN Conversational Programming 3 2014 ...

Page 5: ...Fundamentals ...

Page 16: ...Contents 16 TNC 320 User s Manual HEIDENHAIN Conversational Programming 3 2014 ...

Page 43: ...1 First Steps with the TNC 320 ...

Page 63: ...2 Introduction ...

Page 81: ...3 Programming Fundamentals file management ...

Page 124: ......

Page 125: ...4 Programming Programming aids ...

Page 152: ......

Page 153: ...5 Programming Tools ...

Page 180: ......

Page 181: ...6 Programming Programming contours ...

Page 232: ......

Page 233: ...7 Programming Data transfer from DXF files or plain language contours ...

Page 251: ...8 Programming Subprograms and program section repeats ...

Page 267: ...9 Programming Q Parameters ...

Page 337: ...10 Programming Miscellaneous functions ...

Page 357: ...11 Programming Special functions ...

Page 379: ...12 Programming Multiple Axis Machining ...

Page 406: ......

Page 407: ...13 Manual operation and setup ...

Page 462: ......

Page 463: ...14 Positioning with Manual Data Input ...

Page 468: ......

Page 469: ...15 Test run and program run ...

Page 497: ...16 MOD functions ...

Page 525: ...17 Tables and overviews ...