Working with the file manager

3.4

3

TNC 320 | User's Manual

HEIDENHAIN Conversational Programming | 3/2014

105

Selecting drives, directories and files

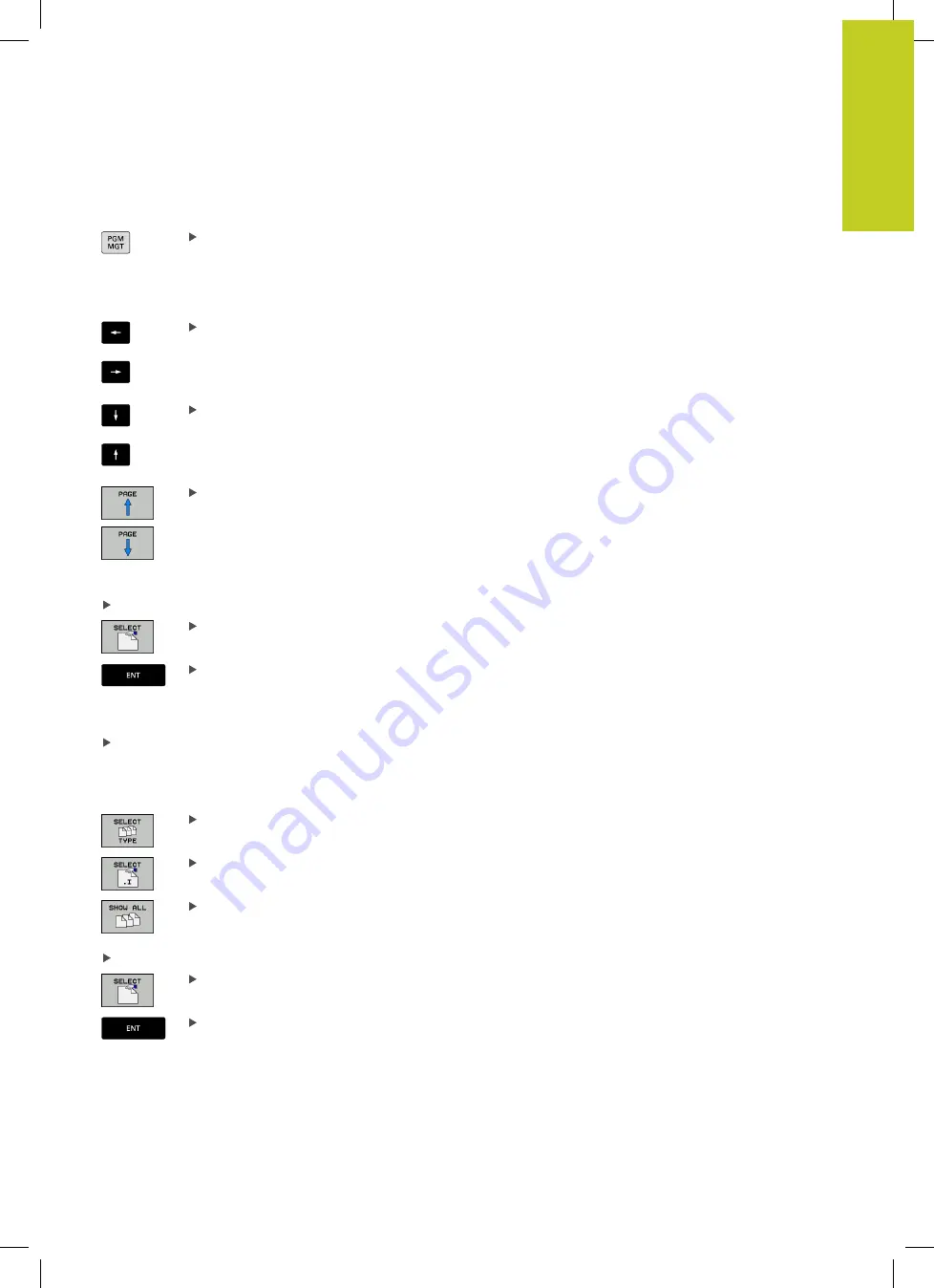

Call the file manager

Use the arrow keys or the soft keys to move the highlight to the

desired position on the screen:

Moves the highlight from the left to the right

window, and vice versa

Moves the highlight up and down within a window

Moves the highlight one page up or down within a

window

Step 1:

Select drive

Move the highlight to the desired drive in the left window

Select a drive: Press the SELECT soft key, or

Press the ENT key

Step 2:

Select a directory

Move the highlight to the desired directory in the left-hand

window—the right-hand window automatically shows all files

stored in the highlighted directory

Step 3:

Select a file

Press the SELECT TYPE soft key

Press the soft key for the desired file type, or

to display all files: Press the SHOW ALL soft key;

or

Move the highlight to the desired file in the right window

Press the SELECT soft key, or

Press the ENT key

The TNC opens the selected file in the operating mode from which

you called the file manager

Summary of Contents for TNC 320

Page 4: ...Controls of the TNC 4 TNC 320 User s Manual HEIDENHAIN Conversational Programming 3 2014 ...

Page 5: ...Fundamentals ...

Page 16: ...Contents 16 TNC 320 User s Manual HEIDENHAIN Conversational Programming 3 2014 ...

Page 43: ...1 First Steps with the TNC 320 ...

Page 63: ...2 Introduction ...

Page 81: ...3 Programming Fundamentals file management ...

Page 124: ......

Page 125: ...4 Programming Programming aids ...

Page 152: ......

Page 153: ...5 Programming Tools ...

Page 180: ......

Page 181: ...6 Programming Programming contours ...

Page 232: ......

Page 233: ...7 Programming Data transfer from DXF files or plain language contours ...

Page 251: ...8 Programming Subprograms and program section repeats ...

Page 267: ...9 Programming Q Parameters ...

Page 337: ...10 Programming Miscellaneous functions ...

Page 357: ...11 Programming Special functions ...

Page 379: ...12 Programming Multiple Axis Machining ...

Page 406: ......

Page 407: ...13 Manual operation and setup ...

Page 462: ......

Page 463: ...14 Positioning with Manual Data Input ...

Page 468: ......

Page 469: ...15 Test run and program run ...

Page 497: ...16 MOD functions ...

Page 525: ...17 Tables and overviews ...