11

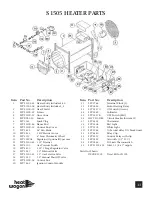

S1505 HEATER PARTS

Item Part No.

Description

1

SFP S1505-55 Heater Body Includes:2,4,5

SFP S1505-56 Heater Body Includes:2, 4

2

SFP SL11B-90 Heat Shield

3

SFP SL11B-53 Screen

4

SFP SL11B-13 Nose Cone

5

SFP BV85-50

Burner

6

SFP 2143

Spark Plug

7

SFP SL11B-86 Flame Rod

8

SFP SL11B-35 Control Box Cover

9

SFP 2423

24” Fan Blade

10

SFP 2432

1 HP Electric Motor

11

SFP 6119

8” Semi Pneumatic Wheel

12

SFP 11SV08

Regulator (Optional)10psi max

13

SFP S1500-83 1.25” Strainer

14

SFP 4509

Gas Pressure Switch

15

SFP 4490

1.25” 2 Stage Regulator Valve

16

SFP 2537

1.5” Solenoid Valve

17

SFP S1505-81 1.5” Gas Selector Valve

18

SFP 2539

1.5” Manual Shut-Off valve

19

SFP SL11B-58 Control Box

20

SFP 7462

Ignition Control Module

Item Part No.

Description

21

SFP 5768

Terminal Block (3)

22

SFP 2436

Motor Starting Relay

23

SFP 3337G

ON Switch (Green)

24

SFP 5989

Voltmeter

25

SFP 3337R

OFF Switch (Red)

26

HWP HC1002

Circuit Breaker for item 20

27

SFP 2453

Thermostat

28

SFP 2506

Red Light

29

SFP 2505

White Light

30

SFP 5988

10-Second delay ON break timer

31

SFP 6440

Relay Clip

32

SFP 4512

Control Relay with clip

33

SFP 5355

Airswitch (0.5” W.C.)

34

SFP 2446

Hi Limit Thermoswitch

35

SFP S1505-152 Inlet, 1-1/4 x 9" nipple

Parts Not Shown

DECDK1505

Decal Kit for S1505