USE ONLY HAYWARD GENUINE REPLACEMENT

PARTS

4

SAVE THESE INSTRUCTIONS

General Information

Introduction

This manual contains information for the proper installation and operation of the Hayward Super Pump

®

700 Series.

The instructions in this manual MUST be followed precisely. Failure to install according to defined instructions

will void warranty.

Product Benefits

Super-sized 110 cubic-inch basket has extra leaf-holding capacity and extends time between cleanings. Rigid

construction with load extender ribbing assures free flowing operation even with heavy debris loads.

Exclusive swing-aside hand knobs make strainer cover removal simple and easy.

See-thru strainer cover lets you see when the basket needs cleaning.

All components molded of corrosion-proof reinforced thermoplastic for extra durability and long life.

Uni-bracket mounting base provides stable, stress-free support, plus versatility for any installation requirement.

Adapts to 48 and 56 frame motors.

Heat resistant, industrial size ceramic seal.

Rugged, one-piece housing, with full-flow ports, assures rapid priming and continuous operation.

Service-ease design gives simple access to all internal parts. By disengaging just four (4) bolts, motor and

entire drive group assembly can be removed, without disturbing pipe or mounting connections.

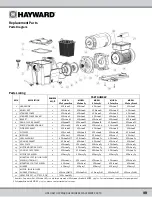

Product Specifications