34

2 1 0 0 B A L E B U S T E R

O P E R A T I N G I N S T R U C T I O N S

Appendix B: 2100 BALEBUSTER Specifications

Gener

Gener

Gener

Gener

General

al

al

al

al

Tractor H.P. Required ............................ See BEFORE OPERATING Min. 60 H.P.

Capacity .................................................. 5-1/2 Ft. Long x 6-1/2 Ft. Dia., 1500 Lbs.

Rotor Length ........................................................................................................ 78"

Rotor Diameter............................................................................................... 25-1/2"

Rotor Bearings - Ball ....................................................................................... 1-3/4"

Knives- Heat-Treated ............................................................................................. 30

Caster Wheel - Taper Roller Bearings - Tire Size .......................... 9.5 L x 14 8-Ply

W

W

W

W

Wor

or

or

or

orking P

king P

king P

king P

king Position:

osition:

osition:

osition:

osition:

Length ................................................................................................................ 153”

Width............................................................................................................ 156-1/2”

Height ........................................................................................................... 116-3/4”

T

T

T

T

Trrrrranspor

anspor

anspor

anspor

ansport P

t P

t P

t P

t Position:

osition:

osition:

osition:

osition:

Length ................................................................................................................ 153”

With Caster Wheel Removed............................................................................. 101”

Width w/Deflector Folded ........................................................................... 122-3/4”

Width w/Tines and Deflector Folded ................................................................. 101”

Height ............................................................................................................. 80-1/4”

2 Point Hookup

P.T.0 ...................................................................................................... 1000 R.P.M.

Dual Hydraulics (single hydraulic system optional) .................................... 1800 psi

Cylinder (2) 2-1/2" x 16" Double Acting

Options

Options

Options

Options

Options

CAT II/III Quick Attach Bracket

Wide Deflector Belting

Stripper plate

Summary of Contents for 2100 BALEBUSTER

Page 2: ...A Tradition of Innovation Since 1966...

Page 4: ...A Tradition of Innovation Since 1966...

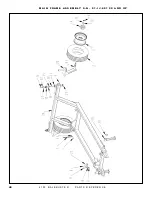

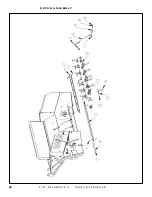

Page 56: ...48 2 1 0 0 B A L E B U S T E R P A R T S R E F E R E N C E R O T O R A S S E M B L Y...

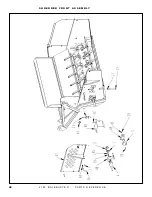

Page 62: ...54 2 1 0 0 B A L E B U S T E R P A R T S R E F E R E N C E B A L E L O A D E R A S S E M B L Y...

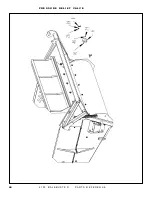

Page 74: ...66 2 1 0 0 B A L E B U S T E R P A R T S R E F E R E N C E O R B I T M O T O R...

Page 76: ...68 2 1 0 0 B A L E B U S T E R P A R T S R E F E R E N C E W H E E L A N D B E A R I N G...