A

B

C

D

E

F

G

H

I

41

4000364740 E12.16

USA

/

GB

H14TX - HB40 - H16TPX - HB44J

C

- Maintenance

4 - Periodic inspection

The Periodic inspection is a thorough inspection of the operation and safety features of the machine.

It must take place before the sale / resale of the machine and at a frequency of 6 months or 1 year

according to regulations. Local regulations may have specific requirements on frequency, and content

of inspections.

Otherwise or in addition, use the detailed program below.

This inspection is the responsibility of the owner, and must be conducted by a qualified technician.

To ensure user safe use and improve the life of machines, HAULOTTE® recommended performing

this inspection every HAULOTTE® months.

This inspection should include the daily inspection.

Intervention to be made after :

• Extensive dismantling and reassembly.

• Repairs involving the machine's essential components.

• Any accident causing stress to the machine.

Visual inspection without

disassembly

Lubrication-Greasing

Tightening

To drain off

Systematic replacement

Summary of Contents for H14TX

Page 2: ...2 4000364740 E12 16 USA GB H14TX HB40 H16TPX HB44J...

Page 14: ...14 4000364740 E12 16 USA GB H14TX HB40 H16TPX HB44J A Safety precautions Notes...

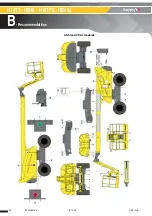

Page 21: ...A B C D E F G H I 21 4000364740 E12 16 USA GB H14TX HB40 H16TPX HB44J B Recommendations Notes...

Page 25: ...A B C D E F G H I 25 4000364740 E12 16 USA GB H14TX HB40 H16TPX HB44J B Recommendations Notes...

Page 26: ...26 4000364740 E12 16 USA GB H14TX HB40 H16TPX HB44J B Recommendations EAC standard...

Page 29: ...A B C D E F G H I 29 4000364740 E12 16 USA GB H14TX HB40 H16TPX HB44J B Recommendations Notes...

Page 30: ...30 4000364740 E12 16 USA GB H14TX HB40 H16TPX HB44J B Recommendations ANSI and CSA standards...

Page 60: ...60 4000364740 E12 16 USA GB H14TX HB40 H16TPX HB44J C Maintenance Notes...

Page 62: ...62 4000364740 E12 16 USA GB Control Filling up Oil tank E001 15 min Notes...

Page 64: ...64 4000364740 E12 16 USA GB Control Oil change Wheel reducer E002 15 mn Notes...

Page 66: ...66 4000364740 E12 16 USA GB Replacement Hydraulic filter cartridge E003 15 min Notes...

Page 68: ...68 4000364740 E12 16 USA GB Filling up Oil change Fuel tank E004 15 mn Notes...

Page 76: ...76 4000364740 E12 16 USA GB Replacement Tightening Wheel E006 15 min Notes...

Page 78: ...78 4000364740 E12 16 USA GB Tightening Screws bolts and nuts E007 15 min Notes...

Page 80: ...80 4000364740 E12 16 USA GB Control Oil change Turntable rotation gearbox E008 15 mn Notes...

Page 86: ...86 4000364740 E12 16 USA GB Control Filling up Battery charge Battery E018 10 min Notes...

Page 88: ...88 4000364740 E12 16 USA GB Lubrication Telescope E022 15 mn Notes...

Page 92: ...92 4000364740 E12 16 USA GB H14TX HB40 H16TPX HB44J D Diagnosis assistance Notes...

Page 102: ...102 4000364740 E12 16 USA GB H14TX HB40 H16TPX HB44J E Electric circuit Notes...

Page 104: ...104 4000364740 E12 16 USA GB H14TX HB40 H16TPX HB44J F Hydraulic circuit Notes...

Page 112: ...2 Electrical diagram H14TX HB40 H16TPX HB44J 1 2 STATION SELECTION...

Page 113: ...3 Electrical diagram H14TX HB40 H16TPX HB44J 1 3 INPUT OUTPUT CALCULAT0R I...

Page 114: ...4 Electrical diagram H14TX HB40 H16TPX HB44J 1 4 INPUT OUTPUT CALCULAT0R II...

Page 115: ...5 Electrical diagram H14TX HB40 H16TPX HB44J 1 5 JOYSTICKS...

Page 116: ...6 Electrical diagram H14TX HB40 H16TPX HB44J 1 6 OPTIONS...

Page 117: ...7 Electrical diagram H14TX HB40 H16TPX HB44J 1 7 OPTIONS...

Page 118: ...8 Electrical diagram H14TX HB40 H16TPX HB44J 1 8 OPTIONS...

Page 119: ...1 Hydraulic diagram H14TX HB40 H16TPX HB44J 1 H14TX HB40 1 1 FOLIO 1 1...

Page 120: ...2 Hydraulic diagram H14TX HB40 H16TPX HB44J 2 H16TPX HB44J 2 1 FOLIO 1 1...