Propeller Owner’s Manual

139

INSTALLATION AND REMOVAL

61-00-39

Page 3-10

Rev. 17 Apr/20

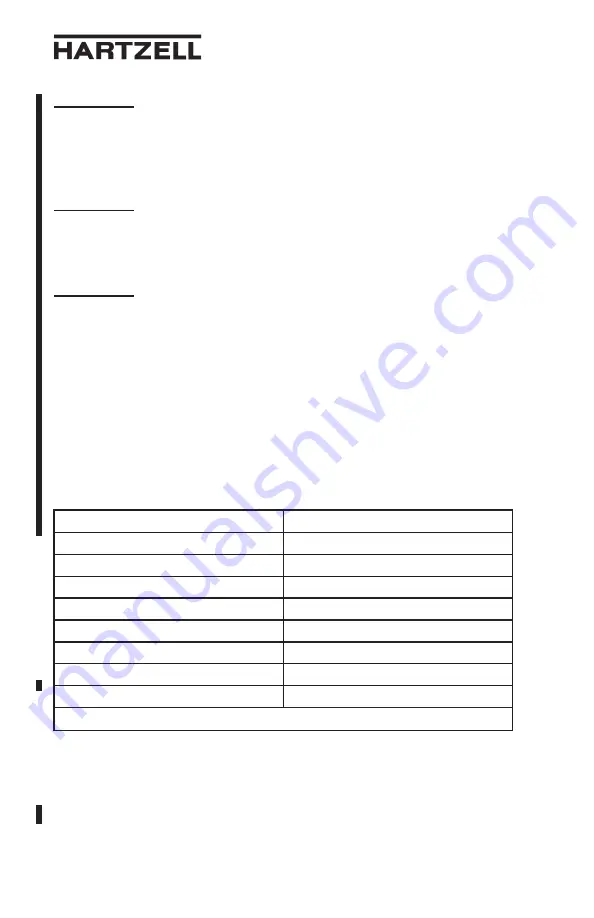

Torque Table

Table 3-2

CAUTION 1: FOR A PROPELLER THAT DOES NOT USE A

LUBRICATED (WET) TORQUE, THE MOUNTING

HARDWARE MUST BE CLEAN AND DRY TO

PREVENT EXCESSIVE PRELOAD OF THE

MOUNTING FLANGE.

CAUTION 2:

TORQUE VALUES WITH “WET” NOTED AFTER

THEM ARE BASED ON LUBRICATED THREADS

WITH APPROVED ANTI-SEIZE COMPOUND

MIL-PRF-83483( ).

CAUTION 3

: REFER TO FIGURE 3-1 FOR TORQUE READING

WHEN USING A TORQUE WRENCH ADAPTER.

Hardware

Torque

A flange mounting bolts

100-105 Ft-Lbs (136-142 N•m) wet

F flange mounting bolts

80-90 Ft-Lbs (108-122 N•m)

N/P flange mounting bolts

100-105 Ft-Lbs (136-142 N•m) wet

W flange mounting nuts

120-125 Ft-Lbs (163-170 N•m)

Spinner mounting bolts

30-40 Ft-Lbs (41-54 N•m)

Piston nut (lock nut)

120 Ft-Lbs (163 N•m)*

Guide rod jam nuts

10 Ft-Lbs (14 N•m)*

Check Nut (beta valve assembly)

9-11 Ft-Lbs (12-15 N•m)

* Torque tolerance is ±10% unless otherwise noted.