III

HARGASSNER Heating technology for

Biomass

A 4952 Weng OÖ Tel.: +43/7723/5274-0 Fax: +43/7723/5274-5 [email protected]

13

2.3

Customer instructions

• Explain cleaning and maintenance intervals

• Explain inspections prior to any fuel refill

• Explain how to operate the boiler and resolve issues.

2.4

Restart boiler

Once the commissioning process has been completed, the boiler can be started

for the first time. Please proceed as follows:

Switch the boiler to manual operation

Use parameter no. 8 to fill the day hopper in manual mode.

Prevents an error due to missing fuel

Switch the boiler to

Auto

or

HWT

mode.

Boiler starts automatically when hot water is needed

2.5

Air flow slider settings

The air flow slider above the ash box is set at the factory.

Classic 12 - 15: one hole line open

Classic 22: all holes lines open

2.6

Inspections prior starting up the boiler

Check the water pressure in the boiler, heat, HWT and accumulator circuits.

Pay attention to the display for notifications (error messages and boiler sta

-

tus).

Rectify any errors.

Check and lock fuel storage room

2.7

Filling the fuel storage room

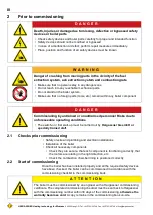

W A R N I N G

Fire hazard

Danger of flue gas being suctioned out of the boiler

Make sure you switch off the boiler before blowing pellets into the storage room!

Protect fuel against moisture

Summary of Contents for Classic 12

Page 64: ......