III

HARGASSNER Heating technology for

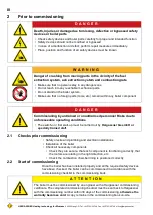

Biomass

A 4952 Weng OÖ Tel.: +43/7723/5274-0 Fax: +43/7723/5274-5 [email protected]

11

Operation

Chapter III: Operation

1

Overview of components

The boiler consists of the combustion chamber and the heat exchanger, and

controls the combustion air with the exhaust fan.

The lambda sensor consistently monitors the flue gases. The integrated sensors

monitor the temperatures of the boiler and the flue gas. The turbulators clean the

heat exchanger through a rod. The boiler cleans itself at regular intervals using

the de-ash system. The ash extraction auger transports the fly ash and the grate

ash into the ash box. The ignition of the pellets takes place through the automatic

Ignition

.

1.1

Function

• Fuel transport from the storage room

• Transport of the fuel into the combustion chamber

• Ignition and combustion of the fuel

• Control of energy transfer to the water based system

• Cleaning of the boiler and the ash extraction into the box

• Evacuation of the flue gases

Pos.

Description

1

Fully refractory-lined combustion chamber

2

Sliding grate

3

Motor for sliding grate

4

Secondary air stream with inlet openings

5

High-temperature insulation plates

6

Primary air

7

Ash box

8

Ignition

9

Stoker auger

10

Circulation zone

11

Heat exchanger

12

Turbulators

13

Automatic heat exchanger cleaning

14

Exhaust fan

15

Full insulation

16

Wood pellet vacuum turbine

17

Pellet-tubes

18

Fuel indicator

19

Pellet day hopper

20

Double rotary valve

21

Drive unit

22

Lambda sensor

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18 19

20

21

Summary of Contents for Classic 12

Page 64: ......