53

4 - Starting up

Hydraulic adjustment of the Convert brackets

Optionally the boom ca has the side adjustment hydraulically, done

from the tractor cabin.

In that case let the above indicated friction pads are just as loos as it

allow the inner tube to slide in and out easily.

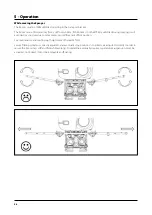

IRIS system setup

The IRIS application system is standard equipped with ceramic hollow

cone nozzles. Each drop leg holds 8 nozzles per drop leg. If a curtain

area of the canopy is not meant to be sprayed, a small valve is fitted as

per two nozzles that allow turning of the spray mist. If only one nozzle

is needed in that area it is as well possible to fit a blind cap.

In the valve A that allows the spray mist to pass on the nozzle, there

is a small no drip valve, that secures when the main switch turns of

the spray mist, that all nozzles stops instantly, and do not spill on the

ground.

The nozzles B are fitted in an adjustable support, in order to angle

them forward accordingly to forward speed, and there by not loosing

spray mist behind the sprayer.

The air outlet has an indicator C that shows the angling of the air

wanes E which are adjusted by pressing bottom D in, and then move

up or down the vanes E.

The air outlet in the lower part shall be orientated upwards to get the

spray mist penetrating from down and upwards. The upper spout shall

point downward in order to avoid drift. Those setting are accordingly

to grot hog the canopy, and adjustment is necessary during the

season, as the size of the canopy change.

In order to get the optimal cross flow effect and penetrate the canopy

the IRIS drop leg shall be set 10º , 15º , 20º or 30º forward, as indicated

in the adjustable part in the top of the drop leg. The forward angling is

set accordingly to forward speed while spraying.

C

B

E

A

D

Summary of Contents for ZENIT 400

Page 2: ......

Page 4: ......

Page 10: ...6...

Page 117: ......

Page 118: ...ILEMO HARDI S A U Poligono Industrial El Segre 712 713 25080 Lleida SPAIN...