5 - Operation

5. 2

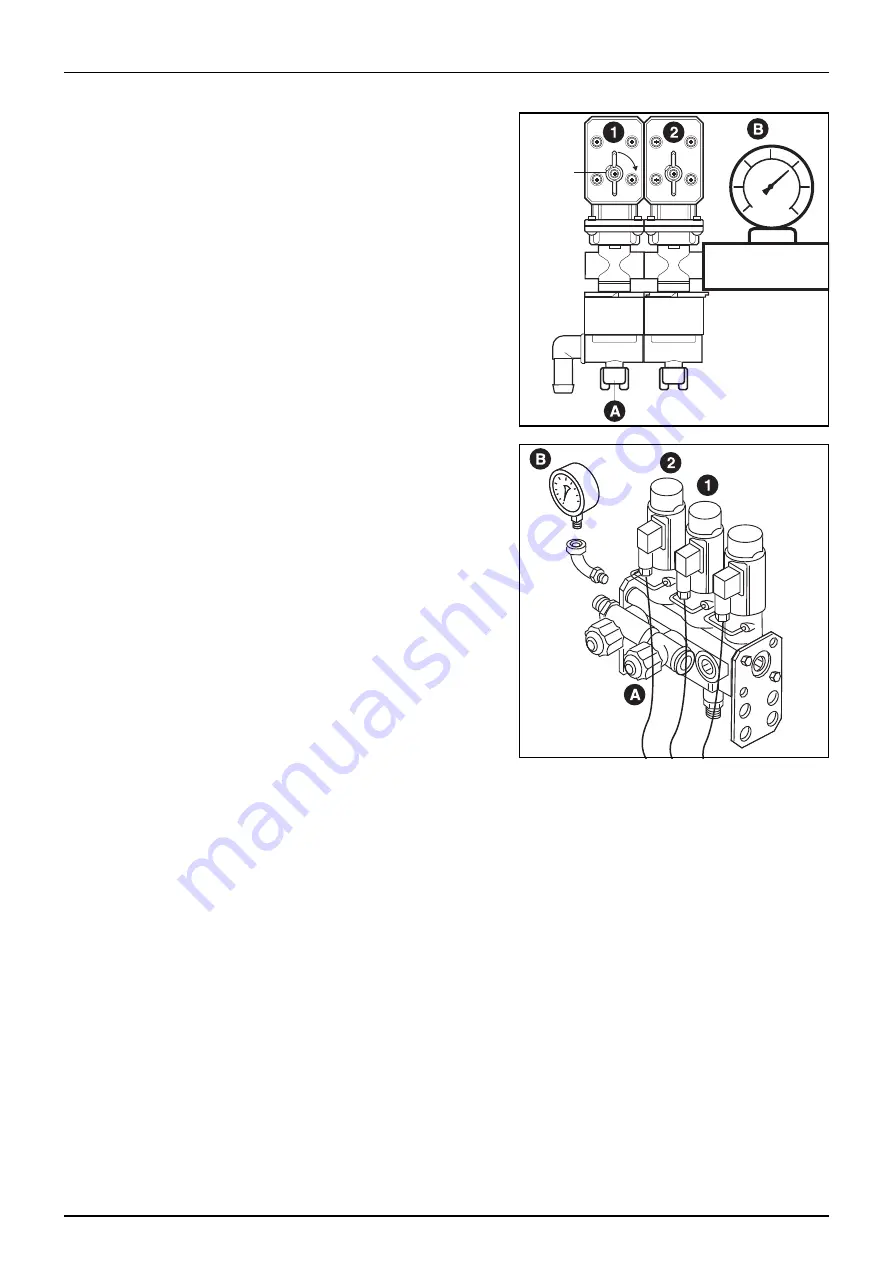

Adjusting Pressure equalisation

Pressure equalisation on machines fitted with HARDI EVC or

Braglia CB/2 control units are adjusted using these steps;

•

With the boom section valves open, run the sprayer at normal

average spraying pressure.

•

Note the reading on the pressure gauge (B)

•

Close the first section valve (1) by turning off at the

switchbox.

•

When system pressure has stabilised, adjust the first

equalisation valve (A) until the original spraying pressure is

restored, then reopen the valve at switchbox.

•

Repeat the procedure until both valves have been balanced.

μ

Attention: After service procedures it is recommended to re-

calibrate equipment before spraying. The equalisation procedure

is generally only required after servicing, changing nozzle size or

when compensating for worn nozzles.

Summary of Contents for Mercury Covamax series

Page 1: ...MERCURY COVAMAX Operator Instruction Manual 67002404 100 HAU 08 2009 www hardi com au...

Page 10: ...Table of Contents TOC 8...

Page 18: ...2 Safety 2 6...

Page 88: ...6 Maintenance 1 18 Maintenance Activity Record Date Service Performed...

Page 92: ...7 Fault Finding 1 4...

Page 100: ...8 Technical Specifications 8 8...