8 - Technical specifications

75

Electrical connections

Rear lights

The wiring is in accordance with ISO 1724.

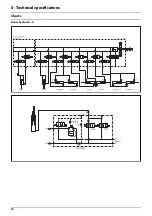

Electrical connections for SPRAY II

39- or 37-poled plug with cable.

Position

Wire colour

1. LH direction indicator

Yellow

2. Free

Blue

3. Frame

White

4. RH direction indicator

Green

5. RH rear position lamp

Brown

6. Stop lamps

Red

7. LH rear position lamp

Black

39-pole

37-pole

SPRAY II

1a

5

S1+

1b

6

S1-

1c

26

End nozzle L

2a

7

S2+

2b

8

S2-

2c

25

End nozzle R

3a

9

S3+

3b

10

S3-

3c

29

+12V sensor

4a

11

S4+

4b

12

34-

4c

4

PWM 1TX

5a

14

S5+

5b

15

S5-

5c

27

GND

6a

16

S6+

6b

17

S6-

6c

13

Optional 5 Reg. feedback

7a

18

S7+

7b

19

S7-

7c

33

Option 1 4-20mA

8a

37

S8+

8b

36

S8-

8c

32

Option 2 Frq

9a

35

S9+/Air angle 0-5V

9b

34

S9-/Fan speed 0-5V

9c

not connected

Option 3/Tank gauge

10a

21

On/off+

10b

22

On/off-

10c

not connected

PWM Output option

11a

23

P

11b

24

Pressure-

11c

28

Flow

12a

20

Foam blop 0-5V

12b

1

Option 4 Rx

12c

31

Speed

13a

3

FM L

13b

2

FM R

13c

30

Gnd sensor

Summary of Contents for MASTER PRO VHH

Page 6: ...Table of Contents 6 ...

Page 8: ...1 EC Declaration 8 ...

Page 12: ...2 Safety notes 12 ...

Page 50: ...5 Operation 50 ...

Page 52: ...6 Maintenance 52 Boom lubrication oiling plan Lift lubrication oiling plan ...

Page 70: ...7 Fault finding 70 ...

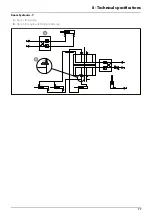

Page 76: ...8 Technical specifications 76 Charts Boom hydraulic Z ...

Page 78: ...8 Technical specifications 78 ...

Page 82: ...HARDI INTERNATIONAL A S Helgeshøj Allé 38 DK 2630 Taastrup DENMARK ...