25

4 - Sprayer setup

General info

Before putting the sprayer into operation

Although the sprayer has been supplied with a strong and protective surface treatment on steel parts, bolts etc. in the

factory, it is recommended to apply a film of anticorrosion oil (e.g. CASTROL RUSTILO or SHELL ENSIS FLUID) on all metal parts

in order to avoid chemicals and fertilizers discoloring the enamel.

If this is done before the sprayer is put into operation for the first time, it will always be easy to clean the sprayer and keep

the enamel clean for many years. This treatment should be carried out every time the protection film is washed off.

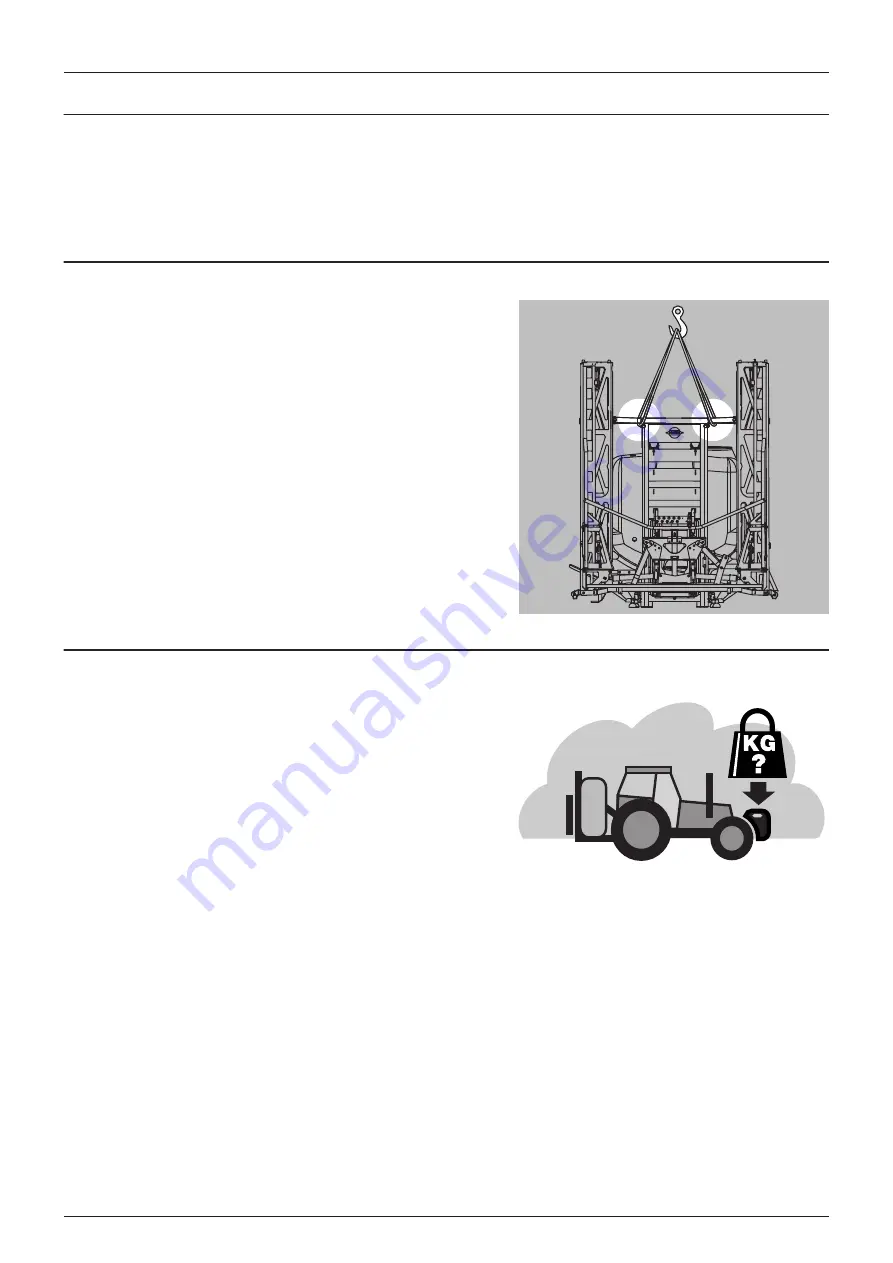

Unloading the sprayer from the truck

For the unloading of the sprayer, you need a crane. When unloading

with a crane please observe the lifting points as shown in the picture,

and make sure that the straps or belts used for lifting are strong enough.

μ

ATTENTION! Only lift the sprayer when the tanks are empty!

Counter balance

μ

ATTENTION! Note the weight of the sprayer. General

recommendations are as follows:

1.

Add ballast to the front of the tractor, if necessary.

2.

Check tyre pressure (see tractor’s instruction book).

3.

Be careful when filling/lifting the sprayer for the first time.

4.

Ensure that the operating unit and the tractor do not touch.

5.

Travel at slower speeds when driving with a full tank, as the tractor braking effect will be reduced.

Summary of Contents for MASTER PRO VHH

Page 6: ...Table of Contents 6 ...

Page 8: ...1 EC Declaration 8 ...

Page 12: ...2 Safety notes 12 ...

Page 50: ...5 Operation 50 ...

Page 52: ...6 Maintenance 52 Boom lubrication oiling plan Lift lubrication oiling plan ...

Page 70: ...7 Fault finding 70 ...

Page 76: ...8 Technical specifications 76 Charts Boom hydraulic Z ...

Page 78: ...8 Technical specifications 78 ...

Page 82: ...HARDI INTERNATIONAL A S Helgeshøj Allé 38 DK 2630 Taastrup DENMARK ...