12

-

22

Hanskamp AgroTech B.V. (the Netherlands)

www.hanskamp.nl/en

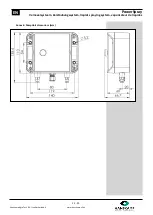

PowerSpray

EN

Vernevelsysteem, Zerstäubungssystem, liquids spraying system, vaporisateur de liquides

Declaration for completed machinery llA

(According to annex VIIA of the Machinery Directive 2006/42/EC, for completed machin-

ery

)

We,

Hanskamp AgroTech BV

Broekstraat 17

7009 ZB Doetinchem

The Netherlands

Authorised compiler(s) of the technical file:

H.J. Hanskamp

Declare entirely under our own responsibility that the product:

Art. nr.: 039

-

011

-

000 t/m 039

-

066

-

000: PowerSpray

Liquid spraying system.

to which the declaration relates, conforms to the provisions of the following directive(s):

-

Machine Directive 2006/42/EG

and completely or partially meets the following essential requirements and that the rele-

vant technical documents were drawn up in accordance with Annex VIIA. The product also

complies with the stipulations in the following annex(es):

NEN

-

EN

-

ISO 12100

NEN

-

5509

We call your attention to the fact where the PowerSpray has not been installed or has

not been installed in accordance with safety measures in these installation and oper-

ating instructions this declaration of stipulations is null and void and so no rights can be

derived from this declaration.

Nederland, Doetinchem 14

-

11

-

2016

H.J. Hanskamp