14

-

23

Hanskamp AgroTech B.V. (the Netherlands)

www.hanskamp.nl/en

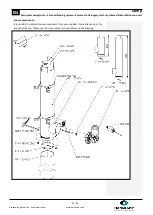

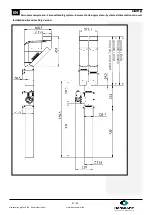

Dump

EN

Carrousel voersysteem—Carousel feeding system—Karussel

-

Fütterungssystem—Système d

’

alimentation carrousel

Warranty limitations:

The warranty excludes costs and expenses due to:

−

Incorrect use of the equipment, not in accordance with the specifications in the

instructions for installation and use;

−

The consequences of any interventions by engineers other than engineers recog-

nised and approved by Hanskamp for carrying out service, maintenance and other

technical work;

−

Incidents such as freezing, ice, fire, flooding, inundation or any other form of ex-

treme water damage, and lightening;

−

Defects in the electrical system or earthing system;

−

Damage to the electrical system caused by vermin and so forth.

The warranty is not applicable to consequential damage that is not related to the feed-

station itself. All systems have been tested. However, in the event of faults, Hanskamp

cannot be held responsible for consequential damage.

List of included amendments in these installation and operating instructions:

Copyright and disclaimer

The information given in this publication is provided for information purposes only and does not constitute an offer for sale. The products supplied may

differ from those illustrated. No part of this publication may be reproduced or made public without prior permission in writing from Hanskamp AgroTech

BV. Although this publication was put together with the utmost care, Hanskamp AgroTech is not liable for any damage that might arise due to errors or

gaps in this publication. The instructions for installation and use in Dutch are the original instructions for installation and use. The translations into other

languages have used the Dutch instructions for installation and use as the source document. Hanskamp AgroTech does not accept any liability for diffe-

rences between the trans

-

lations. If there are doubts about the content and accuracy of the translated instructions for installation and use, the Dutch

instructions for installation and use constitute the authoritative document.

Nr.

Release date

Chapter(s)

Comments

1

11/2016

First release

1.1

11/2017

Dump container introduced