HandiQuilter.com

Page 31

Troubleshooting

HQ 18 Avanté

™

User Manual 1.0

Page 22

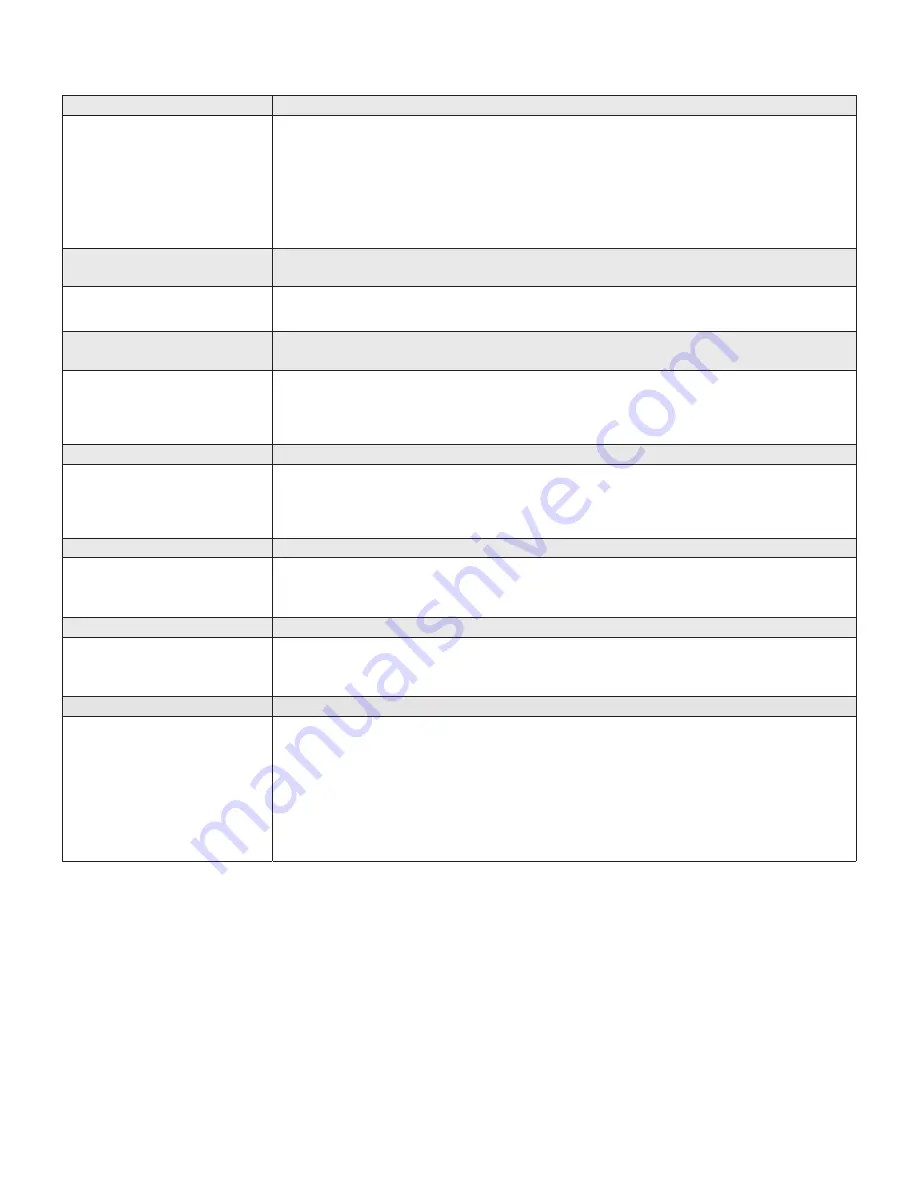

Tension is Poor

Corrective Measure

“Fuzz” caught under the

tension spring in the bobbin

Poorly wound bobbin.

If using short staple threads, inexpensive or industrial threads or coated threads, lint and other

material will build up under the tension leaf spring and begin to lift the spring, reducing the

spring’s ability to compress against the thread. By inserting a needle under the spring and

clearing out the lint, the bobbin tension will return fairly close to its preset tension.

If the bobbin is wound too tight or too loose, this can lead to poor and inconsistent tension. Make

sure when the bobbin is wound that the thread tension is not so tight that the wound bobbin

thread feels hard and causes the bobbin to bulge when it is wound. It should also not be so

loose that the thread is spongy, causing the thread to tangle as it is wound.

Hand Wheel Won’t

Rotate

Corrective Measure

Thread is entangled and

caught in the hook

Turn off the machine and unplug the machine

from the electrical outlet. Lubricate the hook,

strongly turn the hand wheel clockwise and if necessary counterclockwise several times, and

then remove the thread caught in the hook.

Thread Nests Under

Quilt

Corrective Measure

Not enough tension on top

thread

Improper threading

Check that the machine is threaded correctly. Make certain that the thread is flossed snugly in

place between the two tension discs. If machine is threaded correctly, tighten top tension by

rotating the tension knob clockwise.

Refer to threading diagram and threading instructions (page 12).

Hard to Guide Machine

Corrective Measure

Carriage wheels not centered

on track

Thread caught in wheels

Center the carriage wheels on top of the continuous track. Check that the machine carriage has

not “jumped” track.

Remove all thread or debris in wheels. Check that the tracks are free of lint and threads.

Motor Fails to Run

Corrective Measure

On/Off switch turned off

Machine not receiving power

Turn the machine on by using the switch on the back power pod.

Check that the power connector is securely plugged into the back of the machine and the three-

prong end is plugged into the power source.

Uneven Quilt Design

Corrective Measure

Take-up rollers may be

bowed or bent

Leaders are stretched/worn

Make certain the fabric is not rolled too tight, causing the poles to bow. Check that poles are

inserted completely together with the push pin engaged so bowing won’t occur.

If fabric is beginning to stretch or fray, contact Handi Quilter for replacement leaders.

Thread Backlash

Corrective Measure

Bobbin thread tangles within

the bobbin case, tangles and

winds onto the hook spindle,

or occasionally forms loops

on the bottom of the quilt.

The bobbin should sit in the bobbin case such that one side is very minimally above the edge

of the bobbin case and if you lightly press down on the bobbin, it descends slightly into the case.

To adjust the backlash spring, place the bobbin in the case and hold it with the bobbin facing up.

Then use a tiny screw driver to adjust the screw on the outside front shiny surface of the bobbin

case (not the screw inside the bobbin case. Turn the screw counterclockwise to raise the

backlash spring (and raise the bobbin) or turn it clockwise to lower the backlash spring

(and lower the bobbin). After making an adjustment, reinsert the bobbin into the machine,

bring up the bobbin thread, and test stitching. Make additional adjustments if necessary.