22

6 -16

mm

> 16

min 3 mm

1/2 1/2

&

%

/

%

#

$

!

"

!

"

#

$

Bandsaw

N3700 e-classic / N3800 / N4400

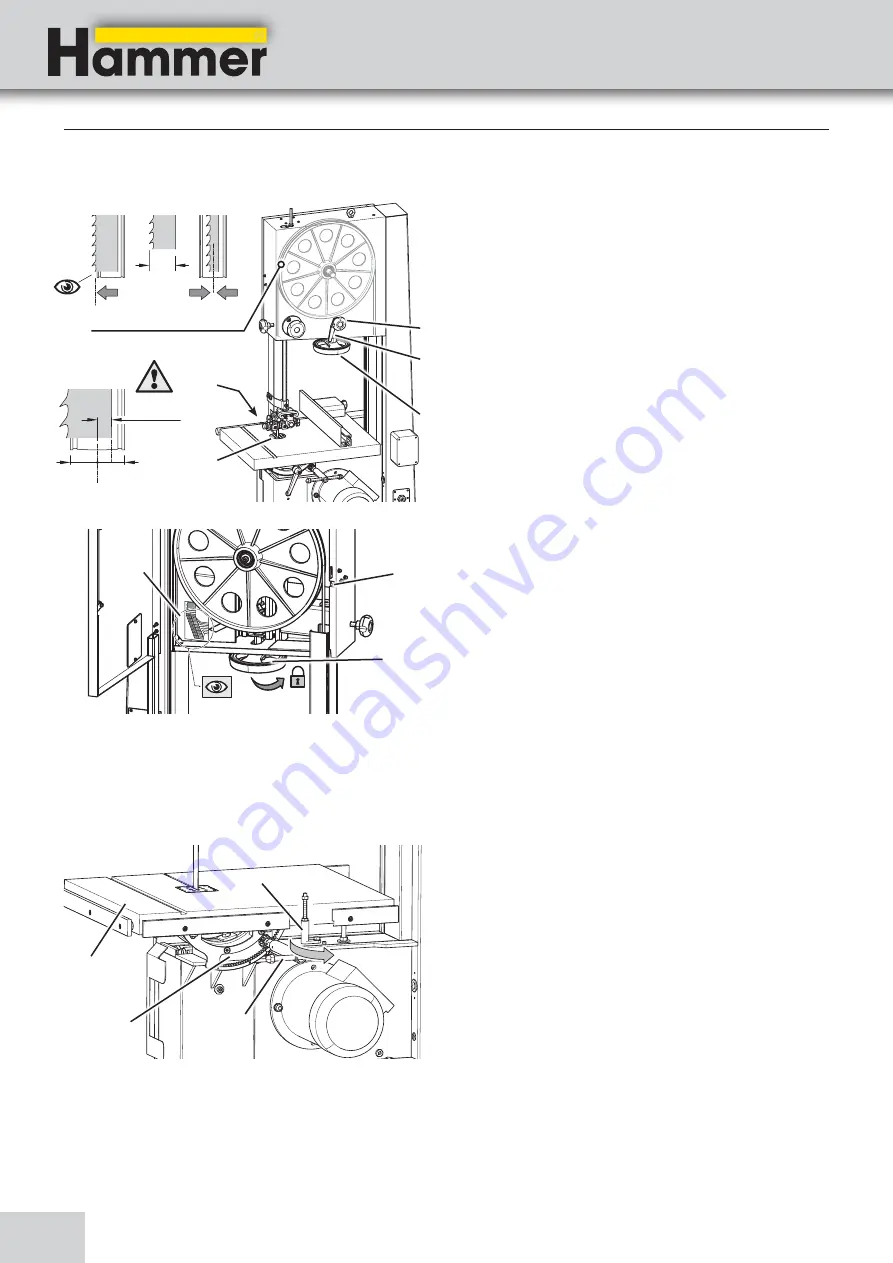

7.3 Saw blade replacement/tension

7.4 Tilting the table

Fig. 7-4: Tilt

The machine working table can be tilted up to an angle

from -5° (N4400: -10°) up to +45°.

Adjusting the angle:

To tilt, remove the table padding to enable the saw belt

to move through the table unimpeded. Open the clam-

ping screw with the supplied spanner and tilt the table to

the desired angle, which is displayed on the mitre scale.

Tighten the clamping screw again.

Tilt -5° or -10°:

• Swing away the stop

• Adjusting the angle

To tilt the table back to its normal position, loosen the

clamping screw once again and tilt the table up to the

stop in the 0° position and clamp it in that position.

(Swing back the stop)

!

Work bench

"

Clamping lever

#

Lever

$

Fence - 0°

Operation

1.

Disconnect the machine from the mains supply.

2.

Remove table insert and positioning pin.

Open wheel door.

3.

Loosen the blade tension hand wheel by turning it

clockwise. Unthread old blade through the machine

table.

4.

Place new saw blade over both wheels (note the di-

rection of the cut!).

Release the clamping lever and set the saw blade

track using the hand wheel:

see sketches

5.

Turn the wheels manually and ensure that the saw

belt glides properly around the wheels and does not

collide with any solid machine parts.

6.

Clamp the clamping lever.

Check the saw blade tension and if required, adjust

with the hand wheel. The values refer to the saw bla-

de width.

Fig. 7-3: Saw blade replacement

!

Positioning pin

"

Table insert

#

Handwheel - Saw blade track

$

Clamping lever

%

Blade tension hand wheel

&

Scale

/

Securing bolt (Optional equipment)