Installation and Service Manual

Appendix

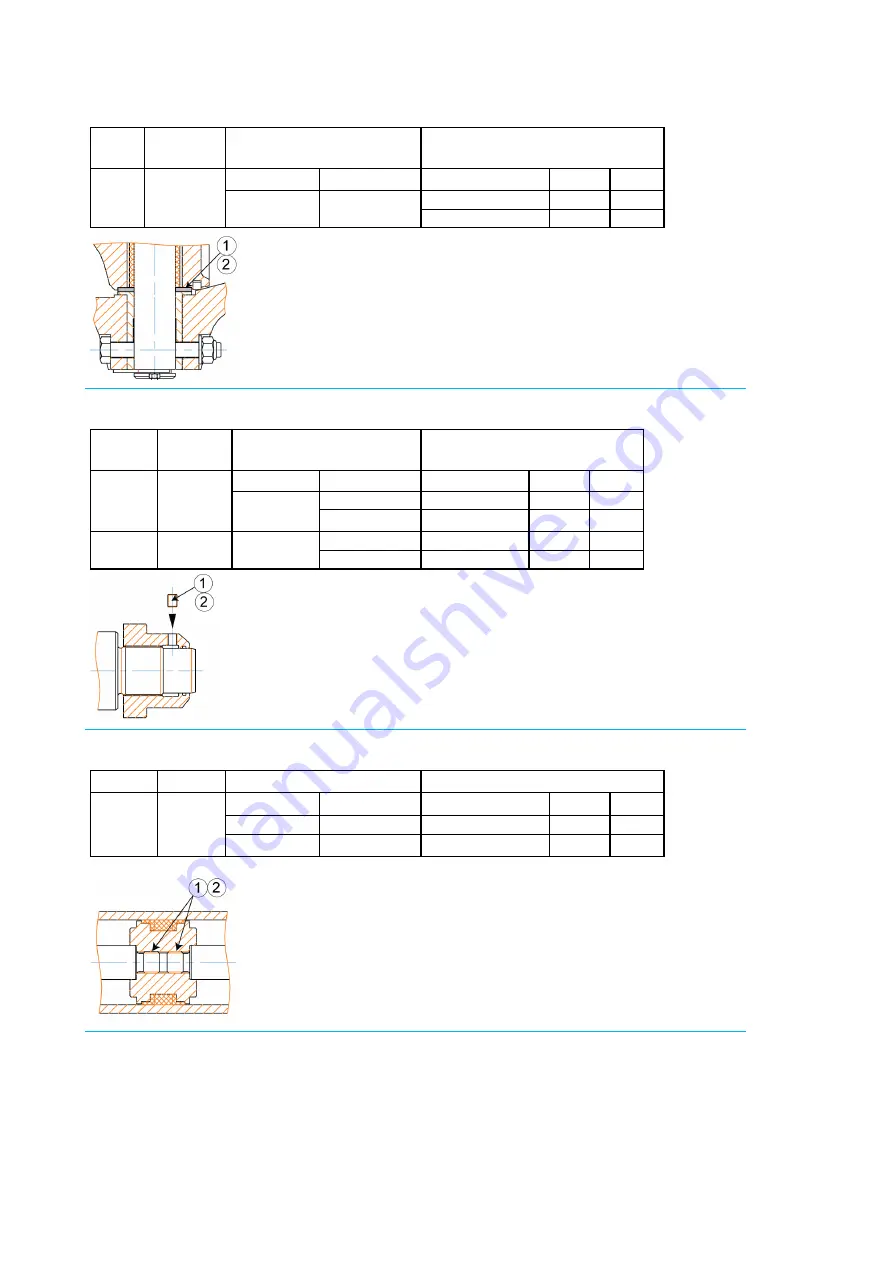

D-Glide Thrust Washers

Loctite Colour

Primer, Activator, Accelerator Loctite Cure Speed with Primer

Activator, Accelerator

325

AMBER

Type

Drying Time

Partial

Full

Activator

1-3 Min

5 Min

24 Hrs

7075

D-glide thrust washer retention (high strength adhesive).

Activator will be used in all retaining applications.

325 Loctite will not cure without the activator.

1 - Apply activator to one side of thrust washer and allow to dry.

2 - Apply Loctite evenly to housing recess.

Press thrust washer into recess, activator side to adhesive.

Remove any excess Loctite from the bush bore.

Hold the washer in place, for approx. 15 minutes, until the bond is firm.

Machine Set Screws, Set Screws, Grub Screws

Loctite

Colour

Primer, Activator,

Accelerator

Loctite Cure Speed

243

BLUE

Type

Drying Time

Partial

Full

Primer 7471

30-70 Sec

With Primer

10 Min

2 Hrs

(Optional)

n/a

Without Primer

20 Min

6 Hrs

222

PURPLE

Primer 7471

30-70 Sec

With Primer

10 Min

2 Hrs

(Optional)

n/a

Without Primer

20 Min

6 Hrs

Machine screws, set screws, grub screws (low strength thread locking).

Primer is used to shorten the cure time when the temperature is below 15°.

1 - Apply optional primer to the thread of the screw and allow to dry. Screws

fitted into bronze do not require primer.

2 - Apply Loctite to the thread engagement area of the screw in sufficient

quantity to fill all engaged threads.

3 Fit the screw to the specified torque.

Cylinder Shafts, Compensator Shafts

Loctite

Colour

Primer, Activator, Accelerator Loctite Cure Speed

263

RED

Type

Drying Time

Partial

Full

Primer 7649

30-70 Sec

With Primer

10 Min

2 Hrs

(Optional)

n/a

Without Primer

20 Min

6 Hrs

Cylinder shafts, compensator shafts (hydraulic, pneumatic thread sealant).

Primer is used to shorten the cure time when the temperature is below 15°.

1 - Apply optional primer to the threads of the shafts and allow to dry.

2 - Apply Loctite to the female threads in the piston and to the threads on the

shafts in sufficient quantity to fill all the threads.

Assemble the shafts and piston as per the drawing specifications.

10-7

Summary of Contents for HJ212

Page 1: ...HJ212 Installation and Service Manual R3A3 Jet unit Manual ...

Page 20: ...Product Description Installation and Service Manual 2 6 ...

Page 56: ...Commissioning Installation and Service Manual 6 4 ...

Page 62: ...Fault Finding Installation and Service Manual 7 6 ...

Page 82: ...Maintenance Installation and Service Manual 8 20 ...

Page 137: ...Installation and Service Manual Appendix Notes 10 21 ...

Page 141: ...Installation and Service Manual Appendix Notes 10 25 ...

Page 164: ...Appendix Installation and Service Manual 10 48 ...

Page 166: ......

Page 169: ......

Page 171: ......

Page 172: ......

Page 175: ......

Page 176: ......

Page 177: ......

Page 178: ......

Page 181: ......

Page 185: ......

Page 186: ......

Page 188: ......

Page 195: ......

Page 196: ......

Page 197: ...Notes ...