87

Page

87

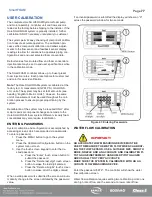

SmartFOAM

concentrates deteriorate rapidly, and residue cannot be left

in the lines.

Note: Approved Class “A” foam concentrates do not deteri-

orate rapidly like Class “B” concentrates. As long as an ap-

proved Class “A” foam concentrate is used and the system

is operated within 10-12 weeks no flushing is required.

When Class “B” foam concentrate is used, always FLUSH

the system, then switch back to Class “A” (Figure 69 and

Figure 74).

1. Energize the apparatus and establish water flow

through a foam capable discharge. Set the fire pump

for a LOW discharge pressure, 50 to 75 PSI (3.4 to

5.2 BAR).

2. Energize the Hale SmartFOAM by pressing the ON

button, allowing foam solution to discharge.

Note: When the Hale ADT, MDTII or MST is in the

FLUSH position the Hale SmartFOAM foam injection

system runs for about twenty (20) second.

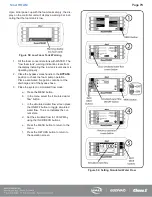

Figure 74: Hale MST Selector Operation

3. Place the Hale ADT, MDT II or MST to the FLUSH

position (

4. Observe the discharge hose and allow Hale Smart-

FOAM and discharge to run for several seconds.

5. After several seconds place the Hale ADT or MDT II

to the TANK “A” position and allow the system to run

until all foam solution is discharged through the

foam capable hose line.

Note: When the Hale MST is used for Class “B”

foam concentrates DO NOT allow the foam pump to

run in the FOAM TANK position after flushing foam

pump.

6. Place the Hale MST to the FOAM TANK position

and allow Hale SmartFOAM to run until Class “A”

foam solution is discharged through the foam capa-

ble hose line. If Class “B” foam concentrate is used,

shut down Hale SmartFOAM immediately after

switching to the FOAM TANK position.

7. Shut down Hale SmartFOAM allowing the foam ca-

pable discharge to continue to flush out the fire

pump discharge manifold as required. Once clear

water flows, close foam capable discharge and shut

down the apparatus.

8. Perform required maintenance checks on the Hale

SmartFOAM and apparatus to return the apparatus

to the ready condition.

IMPORTANT!

MAKE SURE THE HALE ADT OR MDT II IS IN THE TANK

“A” POSITION AND THE HALE MST IS IN THE FOAM

TANK POSITION WHEN APPARATUS IS PLACED IN THE

READY CONDITION.

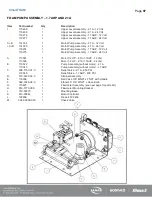

Summary of Contents for MiniCAFS 2.1A

Page 3: ...Page 2 SmartFOAM NOTES...

Page 16: ...Page 15 SmartFOAM SYSTEM DIAGRAM Figure 6 Typical Hale SmartFOAM 2 1A and 1 7AHP System...

Page 17: ...Page 16 SmartFOAM Figure 7 SmartFOAM 3 3 5 0 6 5 Single Tank System with In line Strainer...

Page 18: ...Page 17 SmartFOAM Figure 8 SmartFOAM 3 3 5 0 6 5 Single Tank withMSTandIn lineStrainer...

Page 19: ...Page 18 SmartFOAM Figure 9 SmartFOAM 3 3 5 0 6 5 Single Tank withMSTandFSSeriesStrainer...

Page 20: ...Page 19 SmartFOAM Figure 10 SmartFOAM 3 3 5 0 6 5 Dual Tank withMDTIIandIn lineStrainers...

Page 21: ...Page 20 SmartFOAM Figure 11 SmartFOAM 3 3 5 0 6 5 Dual Tank withMDTIIandFSSeriesStrainer...

Page 22: ...Page 21 SmartFOAM Figure 12 SmartFOAM 3 3 5 0 6 5 Dual Tank withADTandIn lineStrainers...

Page 23: ...Page 22 SmartFOAM Figure 13 SmartFOAM 3 3 5 0 6 5 Dual Tank withADTandFSSeries Strainers...

Page 48: ...Page 47 SmartFOAM Figure 28 Typical 4 Inch Check Valve Installation Midship Pump...

Page 59: ...Page 58 SmartFOAM Figure 43 ADT Option Air Hose Connections Part 2...

Page 68: ...Page 67 SmartFOAM Figure 55 Top Mount Low Level Sensor Assembly...

Page 77: ...Page 76 SmartFOAM NOTES...

Page 90: ...89 Page 89 SmartFOAM NOTES...