L31270 US REV. 8/13 xxMEX ALP

Innovative Vehicle Solutions

OPERATIONAL CHECKS

After repairs are completed and air lines are re con nect ed,

start the engine, build-up pressure to 100 psi, and shut off

the engine. Check for air leaks at the inlet and outlet of the

dryer. Correct any leakage problem. Restar t the engine and

build-up pressure to cut-out pressure. At cut-out pressure

the dryer purge valve opens and im me di ate ly expels a large

volume of air, followed by a slow flow of air lasting

approximately thirty seconds. Check for leakage to assure

that the

PUR

est

Air Dryer will operate properly.

A. Compressor Unloader Mechanism.

B. Governor.

C. Drain Cock and Safety Valve in first (supply) reservoir.

D. All air connections leading to and from the first (supply)

reservoir.

PURGE VALVE INSTALL INSTRUCTIONS

DRAIN ALL AIR FROM THE VEHICLE RES ER VOIRS BEFORE

YOU BEGIN THIS PROCEDURE.

1. Remove the three hex head screws and purge valve cover .

2. Remove large snap ring.

3. With pliers pull out purge valve assembly and discard.

4. Install large and small o-rings on the purge valve assembly .

5. Lubricate the purge piston bore.

6. Insert new purge valve assembly in dryer housing.

7. Install new snap ring.

Service Instructions

PUR

est

®

Air Dryer

Major Repair Kit (RN60AB/RN60AN)

www.haldex.com

Haldex Limited

500 Pinebush Road, Unit #1

Cambridge, ON Canada N1T 0A5

519-621-6722

519-621-3924

Installation

Guide

L31270

Rev. 8/13

When working on air system com po nents the following

pre cau tions should be ob served.

1. Stop engine when working under a vehicle. Always block

the ve hi cle wheels to prevent a fore or aft roll. Bleeding off

system pres sure may cause the vehicle to roll. K eep hands

away from brake chamber push rods and brake adjusters;

they may apply as system pressure drops.

2. Never connect or disconnect a hose or line containing air

pres sure. It may whip as air escapes. Nev er remove a

component or a pipe plug unless you are cer tain all sys tem

air pressure has been exhausted.

3. Never exceed recommended working air pressure and

al ways wear safety glasses when working with air pressure.

Nev er look directly into component por ts or direct a

pressurized air flow at any one.

4. Never attempt to disassemble a component until you have

read and understood all rec om mend ed procedures. Some

components con tain powerful springs and injury can result if

not prop er ly disassembled. Use only proper tools and observe

all precautions per tain ing to the use of those tools.

!

WARNING

PUR

est

®

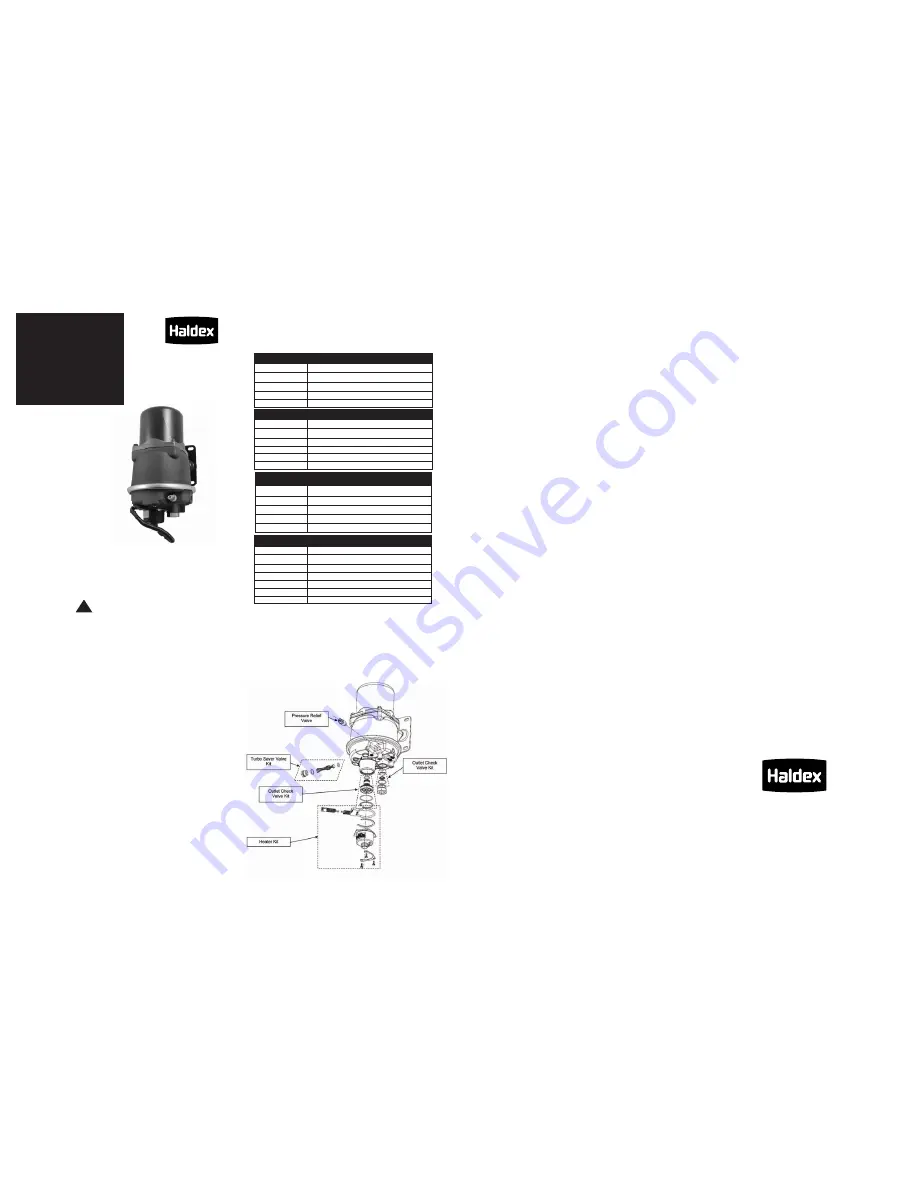

MAJOR REPAIR KIT CONTENTS

(RN60AB/RN60AN)

TURBO-SAVER™ VALVE INSTALL INSTRUCTIONS

DRAIN ALL AIR FROM THE VEHICLE RES ER VOIRS BEFORE

YOU BEGIN THIS PROCEDURE.

1. Remove control port end cap and discard.

2. Disconnect the inlet air line from the dryer .

3. Insert a long shank screwdriver into the inlet por t and press

the Turbo-Saver™ piston out through the control por t and

discard.

4. Install small o-ring on the Turbo-Saver™ piston body.

5. Lubricate the control port bore.

6. Through the control port opening, insert the new

Turbo-Saver™ piston body.

7. Install the o-ring on the new control por t end cap

and thread into dryer. Torque to 35-50 ft. lbs.

8. Reconnect inlet and control air line.

Haldex Brake Products Corporation

10930 N. Pomona Ave.

Kansas City, MO 64153

816-891-2470

FAX: 816-891-9447

OUTLET CHECK VALVE INSTALL INSTRUCTIONS

DRAIN ALL AIR FROM THE VEHICLE RES ER VOIRS BEFORE

YOU BEGIN THIS PROCEDURE.

1. Disconnect the dryer outlet line.

2. Remove outlet end cap.

3. Remove o-ring from end cap. Discard the seal assembly , spring

and o-ring.

4. Install new o-ring on outlet end cap.

5. Install new seal assembly and spring. Seal assembly must be

centered.

6. Thread outlet end cap into dryer body and torque to 3 5-50 ft. lbs.

7. Reconnect outlet air line.

HEATER INSTALL INSTRUCTIONS

1. Disconnect leads of the heater assembly being replaced. If

ambient temperature is <45 ± 8°F, disconnect the battery or

make sure the ignition switch is in OF F position.

2. Remove old heater assembly and discard.

3. Apply the heat conductive g rease in the cavity recess in which

the heater assembly is inserted.

4. Install new heater assembly in the cavity . (The raised thermostat

on the heater body must be placed in the depressed bore in the

dryer body.)

5. Install new gasket, purge valve shield and shield retainer . Install

the three hex head screws. Torque to 30-50 in. lbs.

6. Connect heater wires/connector to vehicle heater

wires/connector.

HEATER OPERATIONAL CHECKS

At temperatures above freezing, the heater circuit will be open. If an

operational check is required, a means must be available to reduce

the temperature of the heater thermostat to below 45 ± 8°F .

1. After installation of the heater is completed, apply ice or other

cold source to the heater plastic body area to lower the

temperature of the thermostat.

2. Connect a continuity meter or a similar device to the heater leads.

3. When the heater thermostat drops to about freezing, the

continuity meter should indicate a closed circuit.

4. Remove the cold source from the heater plastic body area.

5. When the heater thermostat reaches about 65 ± 1 0°F, the

continuity meter should indicate an open circuit

PRESSURE RELIEF VALVE INSTALL INSTRUCTIONS

DRAIN ALL AIR FROM THE VEHICLE RES ER VOIRS BEFORE

YOU BEGIN THIS PROCEDURE.

1. Remove Pressure Relief Valve and discard.

2. Install new Pressure Relief V alve. Torque to 20-35 ft. lbs.

TURBO-SAVER™ VALVE

QTY.

DESCRIPTION

1

Piston

1

Piston O-Ring (1/2 ID)

1

End Cap O-Ring (3/4 ID)

1

Cap Nut

PURGE VALVE

QTY.

DESCRIPTION

1

Drain Valve Assembly

1

Body O-Ring (1 15/16 ID)

1

Piston O-Ring (13/16 ID)

1

Retaining Ring

1

Lubricant (1/4 oz)

OUTLET CHECK VALVE

QTY.

DESCRIPTION

1

Seal Assembly

1

O-Ring (1 5/16 ID)

1

Conical Spring

1

Pressure Relief Valve

HEATER

QTY.

DESCRIPTION

1

Heater Assembly, 28 VDC

1

Gasket

1

Retainer

1

Shield, Purge Valve

3

Hex Head Screw, 10-24 x 5/8” Long

1

Grease, Heat Conductive

Servicing of these assemblies can be ac com plished while the

unit is installed on the ve hi cle.

NOTE "A"

: It is recommended that the desiccant car tridge be

replaced if water/oil is present in the reservoirs. If the dryer has

been in operation for more then three years, it is recommended

that the desiccant cartridge be replaced. Lubricate all o-rings

and seals prior to assembly.