HAKKI PILKE RAVEN

TRANSLATION

VERSION 1-2015

Re-splitting or splitting without cutting

Raise the guard of the cutting and splitting section.

Place the log you want to split in the splitting groove.

Close the guard of the cutting and splitting section.

Move the splitting beam forwards for the desired length by pushing up lever C and return

the splitting beam backwards by pulling down lever C.

The above procedure can be used to split wood without cutting it.

Placing logs on the input table

We recommend the use of auxiliary devices, such as the HakkiFeed 371 timber deck. If a timber deck is not

attached to the machine, the maximum allowed length is 4.5 m. Always lift and place wood on the input

table in a safe manner that does not endanger the operator.

Note! Placing logs directly on the input table with a loader is strictly prohibited.

Note! Ensure that the log's centre of gravity stays on the conveyor.

Sawing the last log

When sawing wood, the second to last piece should be sawn in such a way that the remaining piece is of a

sufficient length. This ensures that the log will stay firmly under the wood gripper and that the sawing will

be steady and safe.

3.4 USING THE OUTPUT CONVEYOR

The Hakki Pilke Raven firewood processor’s output conveyor belt is driven by a hydraulic motor.

The output conveyor can be adjusted laterally and vertically. The following describes how the conveyor can

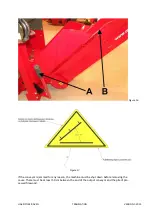

be turned laterally (accessory) by using turning lever A and handle B (Figure 16):

Release the lock of the conveyor by pushing lever A (Figure 16) towards the conveyor, and turn the convey-

or to the desired position with handle B.

The maximum operating angle for the output conveyor is 40°. The maximum angle is indicated on the label

(Figure 17) and the instructions attached to the output conveyor.