HAKKI PILKE RAVEN

TRANSLATION

VERSION 1-2015

Note! In cold weather, the saw valve shaft may be sluggish at first, which means that the saw bar must

be driven to the bottom position a couple of times for the saw chain to run.

9.

Move the splitting beam forward and stop it by opening the cradle guard of the cutting and split-

ting section.

10.

Ensure that the splitting beam moves backwards by pulling down lever C (Figure 15).

11.

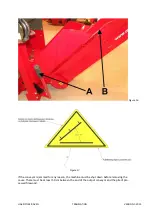

Test run the feed motion of the input conveyor by pushing lever A (Figure 15) to the right.

12.

Visually check that the output conveyor runs at normal speed.

13.

Ensure that the splitting motion or saw chain cannot be activated with the guard open.

If a fault occurs during the test run, determine the cause of the fault and take remedial action as deemed

necessary. The machine must be shut down and disconnected from the power source for the duration of

both the diagnostics and repairs.

Note! Do not leave a running machine unsupervised!

3.3 WOOD FEEDING, CUTTING AND SPLITTING

The input conveyor belt or feed roller feeds the wood to be processed into the machine. Feed wood into

the machine using control lever C (Figure 15 in Section 3.1).

When feeding wood into the machine, make sure that it does not present a risk of your clothes, hands or

other parts getting caught in the machine, such as due to the shape of the log. Do not use your hand to

guide the log into the cutting section. Adjust the measuring device to the desired measurement.

1.

Choose the log to process. Note that the maximum log diameter is 30 cm. The knottiness and shape

of the log can increase the diameter.

2.

Use the input conveyor to feed wood into the cutting section by pushing up lever C (Figure 15 in

Section 3.1).

The input conveyor belt can also be driven forward by pushing lever A (Figure 15) to

the right, especially when the log is further away from the cutting section and a longer and con-

tinuous feed motion is required.

3.

Once the log stops for cutting in the mechanical measuring device, lock the log in place with the

wood gripper by pressing down handle B (Figure 15).

4.

Cut the log by pulling down lever C (Figure 15), which activates the saw chain and lowers the saw

bar. Simultaneously, the splitting beam returns to its initial position.

5.

Return the saw bar to the upper position by pushing up lever C (Figure 15). This moves the splitting

beam forwards and splits the log. Simultaneously, the input conveyor pushes the log forwards for

the next cut.

Note! Only move the splitting beam forward for the required length. For example, if you have ad-

justed the machine for logs of 35 cm in length, the splitting beam needs to move only approx. 37

cm. This notably increases the efficiency of the machine.