55

UTD.123.2019-10.00_EN

Sizes

81 (A, E, G series) and

021A (EP series) are

lubricated for life

, assuming external pollution-

free environment. An overall guide to oil-change interval is given in the table, and assumes pollution-free

surroundings. Where heavy overloads are present, halve the values. Apart from running hours replace or

regenerate synthetic oil at least each 5 years.

8.3 - Lubrication of extruder support (helical and bevel helical, sizes 100 ... 4501

)

The lubrication of extruder support, supplied

WITHOUT OIL

like the gear reducer, is oil bathed and can be

joint or separate compared with the gear reducer's one.

Separate lubrication

1)

The gear reducer must be filled with lubricant with ISO viscosity degree stated in table 8.2b, whereas the

extruder support

– equipped with metallic plug with filter and valve, drain and level – must be filled with

polyalfaolefines basis synthetic oil

with viscosity degree ISO

320 cSt

8.2.d, AGIP Blasia SX, MOBIL SHC

Gear, KLÜBER Klübersynth GEM4, ARAL Degol PAS, BP Enersyn EPX, SHELL Omala S4 WE; approx quantities

see table 8.3.1) and up to level stated on

extruder support

.

Common/Joint lubrication

2)

The

gear reducer

and the

support

must be filled with the same

polialfaolefines basis synthetic oil

, with

iSO viscosity degree stated in table 8.2b and up to

level

stated on the

gear reducer

. For mounting position

B6, during the filling, remove the upper plug positioned on the extruder support in order to facilitate the

air flow from inside. In this circumstance, cause of the elimination of potential residual air, an oil filling up

to level could be necessary.

1)

The inner part of gear reducer is separated from the

extruder support through a seal ring.

2)

The inner part of gear reducer is connected with the

extruder support; the common lubrication is present

on gear reducer and gearmotors 2I sizes 100 ... 360

or in presence of independent cooling unit when it is

used both for gear reducer and extruder support.

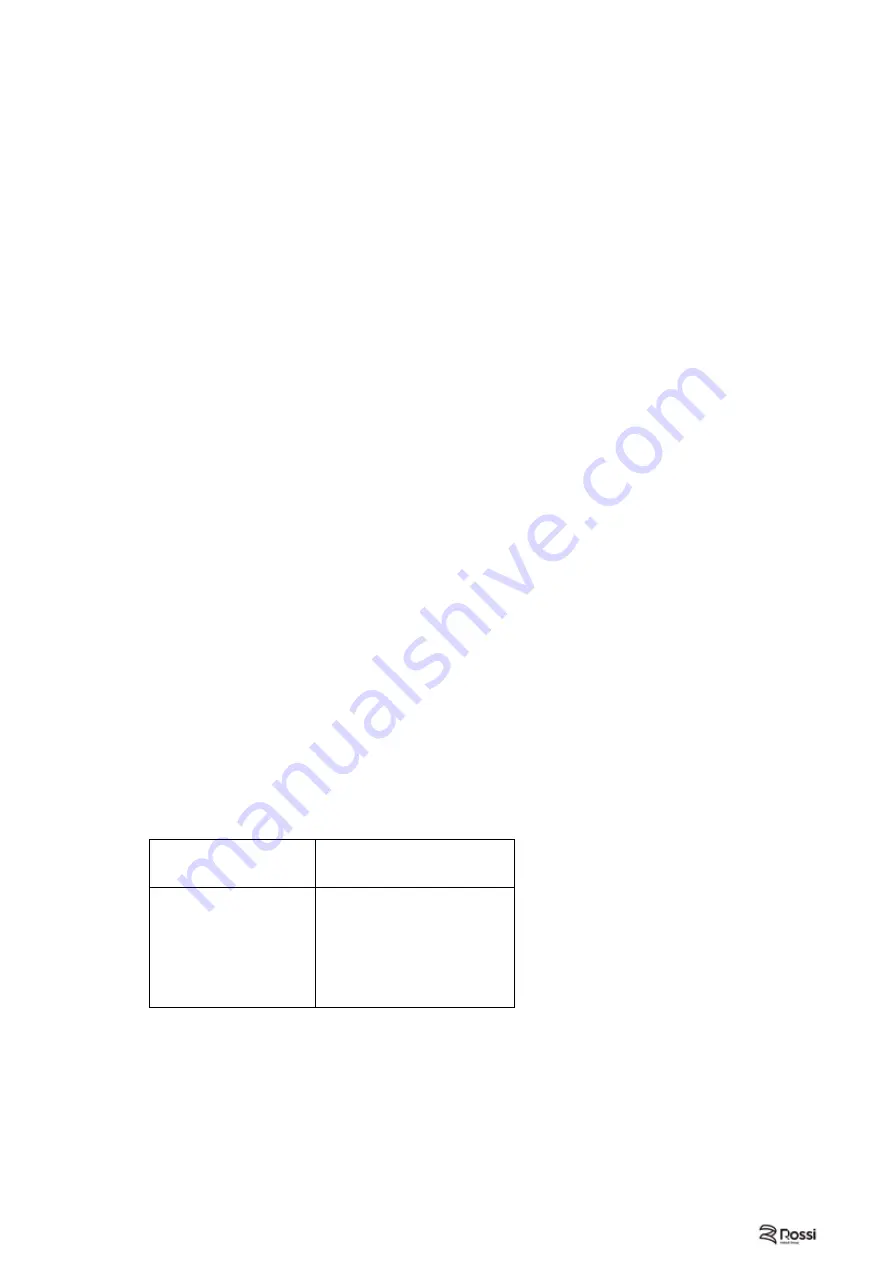

Gear red.

size

Approximate

oil quantity extruder support

l

140, 160

0.8

180

1.1

200

1.5

225

2.5

250, 280

4

320 ... 360

9.1

4000, 4001

20

4500, 4501

16

Grease-lubricated bearings:

Lubrication is «for life» assuming uniform load and pollution-free environment. Replace the grease every

year with running up to 12 h/d and every 6 months with running of 12

÷

24 h/d; in these occasions re-

lubricate the

backstop device

with grease SHELL Alvania RL2. Bearing should be filled with ESSO Gadus

S2 V100 bearing-grease for ball bearings, KLÜBER STABURAGS NBU 8 EP for roller bearings.

Attention!

for bearings requiring greasing refero to ch. 15 ... 20 and consult Rossi in case of doubt.

Combined gear reducers.

Lubrication remains independent, thus data relative to each single gear reducer

hold good.

Output bearings for slewing drives

(

EP series Slewing drives

)

In the case of slewing drives (output designs R-S-H), regardless of the mounting position, the output bearing

has an independent grease lubrication.

The re-lubrication of the bearing has to be carried out at each oil change.

For maintenance intervals

and grease quantity, refer to relevant table 8.2e

It is recommended to re-lubricate bearings and seals with the same grease the gear reducer was supplied;

as alternative, it is possible to use similar grease types.

ATTENTION: the re-lubrication procedure may cause a grease leakage from bearing seat to oil chamber.

This does not affact gear reducer operation. However it is recommended to re-lubricate before replacing

gear reducer oil, in order to remove any grease leaked into oil chamber. For grease quantities follow the data

contained in table 19.1 on page 93.

Table 8.3.1